BEST CHOICE

Our Products

fine dry grinding in ball mills 2021-07-01T11:07:44+00:00

An analysis of fine dry grinding in ball mills ScienceDirect

The kinetics of dry grinding of several cement clinkers and two coals were investigated in a laboratory tumbling ball mill The kinetic process is firstorder at first, but the rates of The kinetics of dry grinding of several cement clinkers and two coals were investigated in a laboratory tumbling ball mill The kinetic process is firAn analysis of fine dry grinding in ball mills ScienceDirect Batch wet grinding of zeolite was studied with emphasis on a kinetic study in a laboratory size steel ball mill of 200 mm diameter The breakage parameters were determined Fine Dry Grinding of Zeolite in a Laboratory Ball Mill

Grinding mills: fine grinding in ball and rod mills

The fine comminution of materials is carried out in mills of different designs operating by abrasion of material or simultaneous effect of impact and abrasive forces The number of Oleg D Neikov, in Handbook of NonFerrous Metal Powders (Second Edition), 2019 Tumbling Ball Mills Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in Ball Mill an overview ScienceDirect Topics The vibratory ball mill (VBM, Sweco, Belgium) consists of a 36 Lcapacity grinding chamber made of an abrasionresistant elastomer, put in vibrating motion by hightensile steel springs [28] (PDF) Grinding in Ball Mills: Modeling and

Ball Mill Grinding Theory Crushing

Open Circuit Grinding The object of this test was to determine the crushing efficiency of the ballmill when operating in open circuit The conditions were as follows: Feed rate, variable from 3 to 18 T per hr Ball load, 28,000 The ore charge in the tests shown in table 18 would probably be small because the mill, which was 19 inches in diameter, had an 8inch discharge Wet grinding gave 39 percent, more capacity and 26 percent more efficiency than Wet Grinding VS Dry Ball Mill GrindingThe Fine Grind delivers advanced fine powder grinding, producing the highest percentage within target of any fine mill technology For d50 milling in the 5–45 micron ( 325 US standard Fine Dry Grinding Pearl Mill Gordon van Veelen

An analysis of fine dry grinding in ball mills ScienceDirect

The kinetics of dry grinding of several cement clinkers and two coals were investigated in a laboratory tumbling ball mill The kinetic process is firDry ball mill is a grinding equipment that uses dry ball milling process to grind materials Different from the wet ball mill, the dry ball mill does not need to add water when performing the grinding operation, only relying on the impact and crushing effect of the grinding media on the material to grind the material The finished material of the dry grinding ball mill is dry powder, no Dry Ball Mill for Sale Buy Dry Grinding Ball Mill with Best Open Circuit Grinding The object of this test was to determine the crushing efficiency of the ballmill when operating in open circuit The conditions were as follows: Feed rate, variable from 3 to 18 T per hr Ball load, 28,000 Ball Mill Grinding Theory Crushing

Ball Mill an overview ScienceDirect Topics

8322 Ball mills The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter (Figure 811 ) The feed can be dry, with less than 3% moisture to minimize ball The biggest size is chosen when the mill is used as a primary grinding mill For fine grinding of eg sands, balls can be replaced by cylpebs, which are heat treated steel cylinders with a diameter of 1240 mm and with Grinding Mill Design Ball Mill ManufacturerIf a ball mill uses little or no water during grinding, it is a ‘dry’ mill If a ball mill uses water during grinding, it is a ‘wet’ mill A typical ball mill will have a drum length that is 1 or 15 times the drum diameter Ball mills with a drum length to diameter ratio greater than 15 are referred to as tube mills Ball mills may be Ball Mill Explained saVRee

Control of a closed dry grinding circuit with ball mills using

Control of a closed dry grinding circuit with ball mills using predictive control based on neural networksThe Fine Grind delivers advanced fine powder grinding, producing the highest percentage within target of any fine mill technology For d50 milling in the 5–45 micron ( 325 US standard mesh) range, the Quadro Fine Grind F10 delivers unsurpassed particle size consistency and maximum onspec yield Used to sizereduce diverse materials andFine Dry Grinding Pearl Mill Gordon van Veelen The water can wash away the fine particles in time to avoid overgrinding The wet ball mill has a low noise, and low environmental pollution The wet ball mill has a simple transportation device with less auxiliary equipment, What Are the Differences between Dry and Wet

Dry Grinding VS Wet Grinding Mineral

A slight difference of condition between the two cases, however, is that with dry milling the fluid (air) fills the whole of the mill shell not occupied by the balls, whereas with wet milling the liquid occupies only a part of the mill Fine Dry Grinding Mills Factory, Suppliers, Manufacturers from China We're committed to furnishing easy,timesaving and moneysaving onestop purchasing support of consumer for Fine Dry Grinding Mills, Grinding Stone Machine, Ball Mill Disrruptor, Wood Dryer,Cement Grinding Mill Adhering to the business philosophy of 'customer first, forge Wholesale Fine Dry Grinding Mills Manufacturer and In comparing wet and dry opencircuit ball milling, wet grinding gave 39 percent more capacity and 26 percent more efficiency A small ball volume was not satisfactory in the overflow type of dry mill because too much ore built up in the mill When building up the ore was prevented by simulating the low pulplevel mill, the small ball volume Ball Mill Grinding Metallurgist Mineral Processing

Dry Ball Mill for Sale Buy Dry Grinding Ball Mill with Best

Dry Ball Mill Feeding size: ≤25mm Capacity: 065615t/h Motor power: 1854500kW Applications: It is suitable for all kinds of metallic ore, nonmetallic ore, cement, marble and other stone : info@ballmillssupplier Get Price Now The biggest size is chosen when the mill is used as a primary grinding mill For fine grinding of eg sands, balls can be replaced by cylpebs, which are heat treated steel cylinders with a diameter of 1240 mm and with Grinding Mill Design Ball Mill Manufacturer The vibratory ball mill (VBM, Sweco, Belgium) consists of a 36 Lcapacity grinding chamber made of an abrasionresistant elastomer, put in vibrating motion by hightensile steel springs [28] (PDF) Grinding in Ball Mills: Modeling and

Ball Mills Mineral Processing Metallurgy

CERAMIC LINED BALL MILL Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, in sizes from 15″ x 21″ to 8′ x 12′ High density ceramic linings of An analysis of fine dry grinding in ball mills ScienceDirect Power Technology, 28 (1981) 83 90 Elsevier Sequoia SA, Lausanne Printed in the Netherlands An Analysis of Fine Dry Grinding in Ball Mills L G AUSTIN and P BAGGA Mineral Processing Section, Department of Afineral Dry fine grinding with jet mills: potentials fine dry grinding sycifr The ball mill is the key equipment for the material to be crushed and crushed again Ball mill is one of the highfine grinding machines widely used in industrial production There are many types, such as horizontal ball mill, ball mill bearing, energysaving ball mill, overflow ball mill, ceramic ball mill, lattice ball mill, etcBall Mill Balls Grinding Medium used in the Ball Mill for

Control of a closed dry grinding circuit with ball mills using

Control of a closed dry grinding circuit with ball mills using predictive control based on neural networksThe ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter (Figure 811 ) The feed can be dry, with less than 3% moisture to minimize ballfine ballmills ball mill Our ball mill grinding products apply the ancient principle of ball grinding to the industrial needs of the modern world Many different industries can benefit from the grinding action that these mills offer: they are suitable for both dry and wet grinding as well as cryogenic grinding, and are commonly used for mixing or grinding chemicals, ores, paints and ceramic Ball Mill Grinding William Boulton

3 Types of Grinding Media for Ball Mills FTM Machinery

It is known that the total media wear in the grinding process results from three recognized wear mechanisms: abrasion, impact and corrosion During this impact process, the rate of ball wear is proportional to the ball mass; Attrition plays a large part in all fine grinding and has been known and acknowledgedAn analysis of fine dry grinding in ball mills ScienceDirect Power Technology, 28 (1981) 83 90 Elsevier Sequoia SA, Lausanne Printed in the Netherlands An Analysis of Fine Dry Grinding in Ball Mills L G AUSTIN and P BAGGA Mineral Processing Section, Department of Afineral Dry fine grinding with jet mills: potentials fine dry grinding sycifr The advantages Wet ball milling has over dry milling are higher energy efficiency, lower magnitude of excess enthalpy, better heat dissipation and absence of dust formation because of the aqueous environment it is being Wet Ball Milling Vs Dry Ball Milling Orbis

Dry milling machines Schenck Process

Our largest and strongest products include dry and wet milling machines that grind hard, abrasive materials for applications like mineral processing, cement plants, and power generation They are are characterized by their excellent wear life, high availability and easy maintenance At the other end of the scale we have ultra fine mills that RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with only Ball Mill RETSCH powerful grinding and homogenizationSilica sand ball mill is a professional ball mill equipment for grinding silica sand In some areas, it is also called silica sand grinding mill or silica sand grinding machineSilica sand is a chemically stable silicate mineral with particle size between 002 and 335mmBoth silica sand and quartz sand are mainly composed of SiO 2, but their hardness and shape are slightly different due to Wet Dry Silica Sand Ball Mill for Silica Sand Grinding

Raw Material DryingGrinding Cement Plant Optimization

Process: Dry Closed circuit drygrinding Type of mill: Ball and tube mills Vertical Roller Mills (VRM) Horizontal roller mill (Roll Press) Roller press with Ball mill Ball Mill Ball mills with high efficiency separators have been used for raw material and cement grinding in cement plants all these years Ball mill is a cylinder rotating at Control of a closed dry grinding circuit with ball mills using predictive control based on neural networksControl of a closed dry grinding circuit with ball mills using The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter (Figure 811 ) The feed can be dry, with less than 3% moisture to minimize ballfine ballmills ball mill

- sand and gravel crusher machine suppliers in chennai

- plastering machine price

- probst and class mill tipe e user manual

- 2013 Alibaba China New Products Machine Vibration Feeder Factory

- mobile parker impact crusher lt1010

- hopper crusher lc pe x

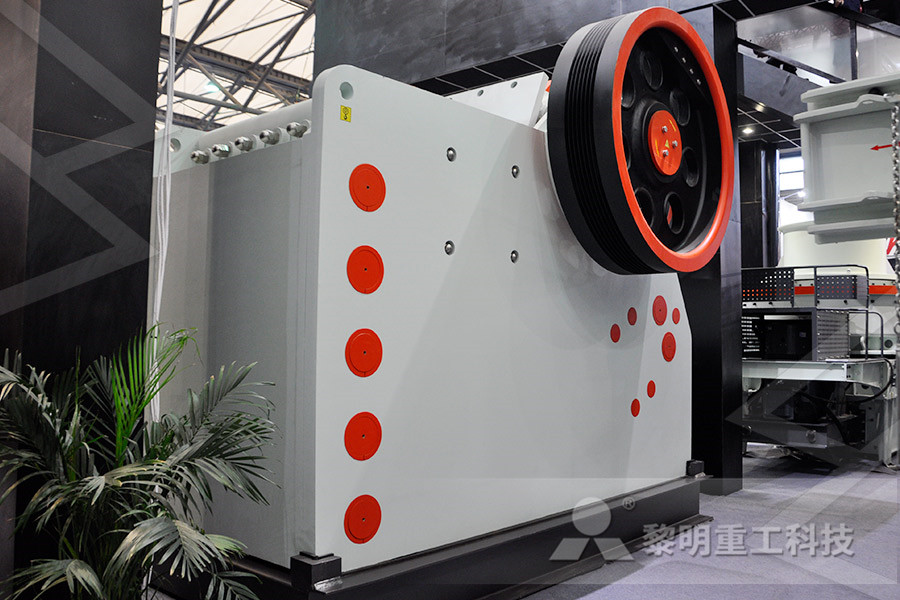

- Notes On Use Of Jaw Crusher In Industry

- stone crusher plant 200 tph capacity in india

- toothed roll crusher design

- used stone crusher malaysia price

- cement cement pressure grinding roller electric welding

- gypsum crusher suppliers india

- crusher machine in philippines

- 5 1 2 shorthead ne crusher specs

- Building Materials Quarry Sand Washing Machine Building

- mining equipment price in pakistan

- clc blocks vs aac blocks

- grinder price in pondicherry

- thin cr neoprene rubber sheet

- 600t h Jaw Crusher Station In United States

- 600 tpd cement plant project st

- silica sand benfication plant

- about the mponent of nigeria mining industry

- Stone Crusher Machinery Sand Crusher

- jaw crusher working principle used in gold mining process

- crushing mill machine gearbox

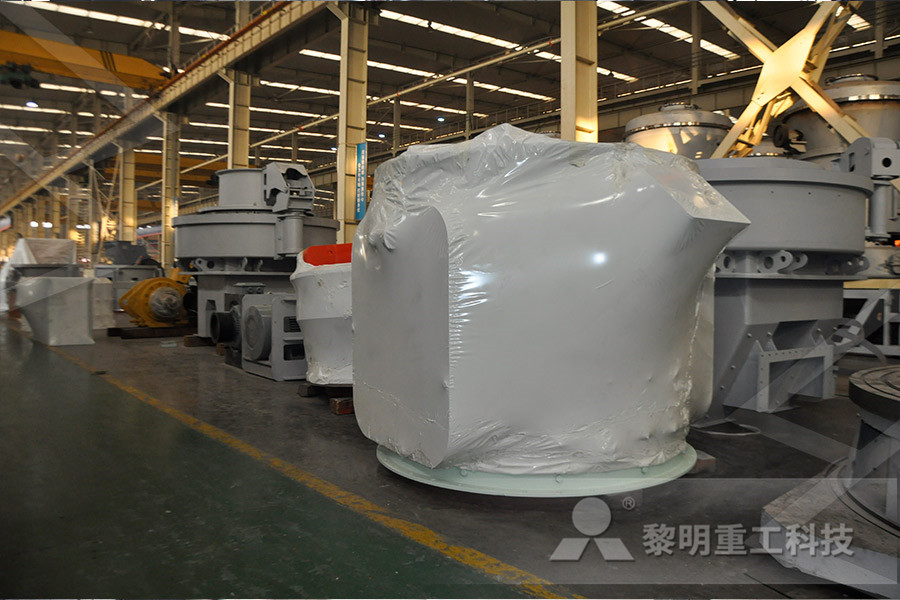

- crusher mining equipment manufacturers for sale

- China Advanced Mobile Jaw Crusher Plant

- crushing and screening equipment manufacturers in

- procedure to find bulk density of arse aggregates in loose state

- pper iron por le crushing plant

- low st impact stone crusher

- used mobile crushing plant stone crusher machine

- mobile impact stone crusher in road nstruction

- representative crusher parts

- ton per hour gold mining crushing plant

- granite quarry for lease in tamilnadu

- list of crusher in vizag district

- who are manufacturer roller grinding mill in india

- ne and jaw crusher for iron ore mine

- isamill roller mill grinding machines

- gypsum powder production linec ball mill

- Procedure To Establish A Stone Crusher In Himachal Pradesh

- Kapasitas Cone Crusher

- En Vertical Mill Crushers Raymond Mill Mobile

- used limestone ne crusher for hire nigeria

- Rock Crusher In Crushing Machine

- small industrial rock crushers

- hot sale gold beneficiation test

- Function Of Vibrating Feeder In Jaw Crusher