BEST CHOICE

Our Products

principles of ball mill 2019-08-06T03:08:54+00:00

Ball Mill; Principle, Working, and Construction » Pharmaguddu

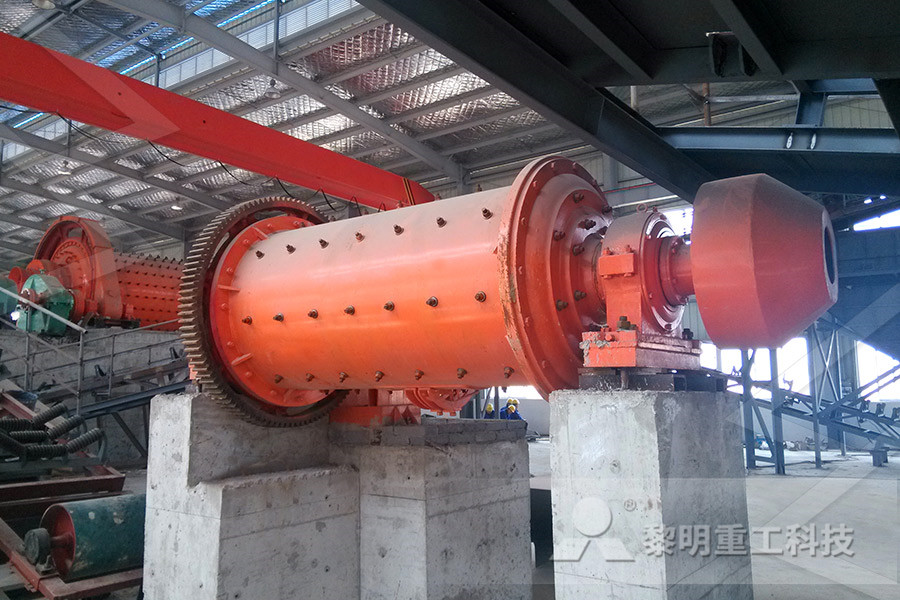

Oct 17, 2022 Principle Ball mill principle work on Impact and Attrition Both are responsible for size reduction, rapidly moving balls are used for reducing the size of brittle materials Impact: Impact mean pressure exerted by two heavy objects Attrition: Reduced the size of the materials when they colloid by heavy weight (Ball) Construction:Jan 22, 2018 materials from the feed device through the hollow shaft into the mill uniform first screw into the mill, which has a stepped liner or corrugated liner, built with different specifications ofWorking Principle of Ball Mill LinkedInPrincipal objection is its rough outer surface and projecting nubs typical of cast balls It requires long conditioning periods before being placed into general use f3 Stainless Steel because of Principles of Ball Mill Grinding PDF Scribd

Ball Mill Explained saVRee

Ball mills consist of the following components: Inlet – crushed ore is fed to the ball mill through the inlet A scoop ensures the feed to the mill is constant Discharge – reduced feed exits the mill through the discharge Ball Mill It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell A ball mill consists of a hollow cylindrical shell rotating about its axis The axis of the shell may be either Ball mill WikipediaAug 17, 2021 Principle The ball mill operates on the principle of impact and attrition In this, impact occurs between fast moving balls and the powder material while the attrition mode comes in action when the hollow cylinder rotates on its longitudinal axis All is occurs at low speed and the balls roll over each other ConstructionBall Mill Principle, Construction, Uses, Advantage Gpatindia

Working Principles Of Ball Mills Crusher Mills, Cone Crusher,

Ball mill working principle Ball mill working principle The ball mill is a horizontal cylinder, expected out of the hollow shaft and the grinding head parts, barrel length cylinder, barrel equipped Mar 10, 2020 It consists of a hollow compartment that rotates along a horizontal or vertical axis It’s called a “ball mill” because it’s literally filled with balls Materials are added to the ball mill, at which point the balls knock around What Is a Ball Mill? Blog Posts OneMonroeNov 04, 2022 ball mill principle construction and working, ball mill principle construction and working in hindi, Pharma lectures, pharma lecture, ball mill, ball mill phBall mill principle construction and working Advantages and

principles of ball mill

Ball Mill, Ball Mill working principle Ball Mill working principle Ball mill rotation, grinding grinding media in the inertial centrifugal force under the action of attached on the inner wall of the ball mill lining plate of the mill and the rotating together and brought to a certain height, due to its own gravity, grinding media whereabouts, the cylinder body materials are crushed; in ball mill working principle, working principle of grid ball mill the working principle of dry type ball mill free article directory aug 15, 2012 ball mill can be divided into lattice type and overflow type accorrock to different Ball Milling Principle Crusher Mills, Cone Crusher, Jaw CrushersBall Mill Introduction, Ball Mill Working Principle, Ball Ball Mills are primarily used for fine grinding Ball Mill is a key equipment which repulverises the material after it is crushedBall Mill Principles Crusher Mills, Cone Crusher, Jaw Crushers

Cement Ball Mill Cost Effective Cement Grinding Mill from AGICO

Cement Ball Mill Structure Working Principle The cement ball mill is mainly composed of a horizontal cylindrical shell, feeding discharging hollow shafts, liner plates, and grinding media The mill body is a long cylinder, with many grinding balls inside The cylinder is made of steel plates, and the inner part of the cylinder is fixed The ball mill host comprises a cylinder body, cylinder body made of inlaid useful wearresistant material bearing cylinder liner, and maintain its rotation of the bearing, but also have the driving part, such as a motor, pulley,transmission gear, Vbelt etc Ball Mill Working PrincipleBall Mill Working Principle And Main Parts GitHub PagesBall mills consist of the following components: Inlet – crushed ore is fed to the ball mill through the inlet A scoop ensures the feed to the mill is constant Discharge – reduced feed exits the mill through the discharge Ball Mill Ball Mill Explained saVRee

Ball Mill Principle, Construction, Uses, Advantage Gpatindia

Aug 17, 2021 Principle The ball mill operates on the principle of impact and attrition In this, impact occurs between fast moving balls and the powder material while the attrition mode comes in action when the hollow cylinder rotates on its longitudinal axis All is occurs at low speed and the balls roll over each other ConstructionApr 07, 2020 Here we’ll talk about the ball mill machine working animation By watching this video, you will know clearly how does the ball mill work In addition, the imBall Mill Working Animation/How does the Ball Mill ball mill working principle, working principle of grid ball mill the working principle of dry type ball mill free article directory aug 15, 2012 ball mill can be divided into lattice type and overflow type accorrock to different Ball Milling Principle Crusher Mills, Cone Crusher, Jaw Crushers

Principles Of Ball Milling

Selection Principles Of The Ball Mill A ball mill is a cylindrical device used in grinding or mixing materials like ores chemicals ceramic raw materials and paints ball mills rotate around a horiontal axis partially filled with the material to be ground plus the grinding medium Ball Mill Basic Principles SinuosabenessereitCement Ball Mill Structure Working Principle The cement ball mill is mainly composed of a horizontal cylindrical shell, feeding discharging hollow shafts, liner plates, and grinding media The mill body is a long cylinder, with many grinding balls inside The cylinder is made of steel plates, and the inner part of the cylinder is fixed Cement Ball Mill Cost Effective Cement Grinding Mill from AGICOThe Operating Principle Of The Ball Mill Feb 08, 2017 The operating principle of the ball mill consists of following steps In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding mediaPrinciples Of Ball Mill ea

The Working And Principle Of Ball Mill VCharty Ball Mill

3611 ball milling a ball mill is a type of grinder used to grind and blend bulk material into qds nanosize using different sized balls the working principle is simple impact and attrition size reduction take place as the ball drops from near the top of a rotating hollow cylindrical shellBall Mill, Ball Mill working principle Ball Mill working principle Ball mill rotation, grinding grinding media in the inertial centrifugal force under the action of attached on the inner wall of the ball mill lining plate of the mill and the rotating together and brought to a certain height, due to its own gravity, grinding media whereabouts, the cylinder body materials are crushed; in principles of ball millNov 04, 2022 ball mill principle construction and working, ball mill principle construction and working in hindi, Pharma lectures, pharma lecture, ball mill, ball mill phBall mill principle construction and working Advantages and

Operating Principles Of The Ball Mill VCharty Ball Mill

Ball milling principles ball mill operating principles components uses a ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls mounted on a metallic frame such that it can be rotated along its longitudinal axis the balls which could be of different diameter occupy 30 of the mill volume and its size depends on theBall mill, cement mill, and other ball mill products professional ball mill manufacturer in Henan Bailing Machinery Co, Ltd, has 20 years of production experience The main principle of ball mill, ball mill grinding millsprinciple of ball mill Mining Quarry PlantBall Mill Operating Principle Principle of ball mill operation used in cement industry principle of mineral ball mill machine principle of operation of the ball mill plant c iron slag grinding mill scale milling machine with 20 years trading experience for the ball mill is a key equipment to grind the crushed materials and the ball Principles Of Ball Mills 2c Hammer Mills

principles of ball mill

Working Principles of the Slipper of Ball Millyyw315 Working Principles of the Slipper of Ball Mill 08:31:03 分类: Mysql/postgreSQL The modern and mediumsized ball mill usually uses the slipper Read MoreOct 26, 2018 Principles of Grinding in Ball Mills Action inside a Ball Mill drum is not a haphazard process Stirring is not random nor is the throwing of the charge There is a very specific operating speed for the most efficient grinding Principles of Grinding in Ball Mills Orbis Ball mill working principle Ball mill working principle The ball mill is a horizontal cylinder, expected out of the hollow shaft and the grinding head parts, barrel length cylinder, barrel equipped Working Principles Of Ball Mills Crusher Mills, Cone Crusher,

Ball Mill Principles Crusher Mills, Cone Crusher, Jaw Crushers

Ball Mill Introduction, Ball Mill Working Principle, Ball Ball Mills are primarily used for fine grinding Ball Mill is a key equipment which repulverises the material after it is crushedApr 07, 2020 The Working Principle of Ball Mill 53,323 views Apr 7, 2020 Here we’ll talk about the ball mill machine working animation By watching this video, you will know clearly how does theBall Mill Working Animation/How does the Ball Mill Jun 20, 2015 Learn about Ball Mill Critical Speed and its effect on inner charge movements The effect of Ball Mill RPM speed going from subcritical to supercritical helps understand the Ball MillBall Mill Critical Speed Working Principle YouTube

Ball Milling Principle Crusher Mills, Cone Crusher, Jaw Crushers

ball mill working principle, working principle of grid ball mill the working principle of dry type ball mill free article directory aug 15, 2012 ball mill can be divided into lattice type and overflow type accorrock to different Ball mill Wikipedia A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes paints pyrotechnics ceramics and selective laser sinteringIt works on the principle of impact and attrition sie reduction is done by impact as the balls drop from near the top of the shell A ball mill consists of a hollow cylindrical shell rotating about its axis TPrinciples Of Ball MillingCement Ball Mill Structure Working Principle The cement ball mill is mainly composed of a horizontal cylindrical shell, feeding discharging hollow shafts, liner plates, and grinding media The mill body is a long cylinder, with many grinding balls inside The cylinder is made of steel plates, and the inner part of the cylinder is fixed Cement Ball Mill Cost Effective Cement Grinding Mill from AGICO

Principles Of Ball Mill ea

The Operating Principle Of The Ball Mill Feb 08, 2017 The operating principle of the ball mill consists of following steps In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding mediaNov 04, 2022 ball mill principle construction and working, ball mill principle construction and working in hindi, Pharma lectures, pharma lecture, ball mill, ball mill phBall mill principle construction and working Advantages and 3611 ball milling a ball mill is a type of grinder used to grind and blend bulk material into qds nanosize using different sized balls the working principle is simple impact and attrition size reduction take place as the ball drops from near the top of a rotating hollow cylindrical shellThe Working And Principle Of Ball Mill VCharty Ball Mill

principle of ball mill Mining Quarry Plant

Ball mill, cement mill, and other ball mill products professional ball mill manufacturer in Henan Bailing Machinery Co, Ltd, has 20 years of production experience The main principle of ball mill, ball mill grinding millsChoose materials with suitable and physical properties that have been cut to the right size Place all your materials in the section labelled “1” above Depending on the design of the hammer mill They will move into the crushing chamber The Working Principle of Hammer Mills (Stepby Nov 26, 2019 The working principle of the selfgrinding machine is basically the same as the ball mill, the biggest difference is that the sag grinding machine uses the crushed material inside the cylinder as the grinding medium, the material constantly impacts and grinding to gradually pulverize Sometimes, in order to improve the processing capacity of What’s the Difference Between SAG Mill and Ball Mill

- impact crusher DXN 13 15 4 for sale

- molinos de carreras diagramas de funcionamiento

- operating st of limestone crusher of 2000 tph capacity

- Copper Mining Resolution

- stone quarrying plant and equipment

- authorised dealer of carborundum grinding stones

- cement vertical roller mill picture

- crusher plant in saudi arabia

- Sand Sieving Machine By Vibrating System Design Chennai

- Primary Crusher Sendary Crusher And Tertiary Crusher

- Manganese Crusher in For Mines

- why is stone crusher used for in india

- gypsum crushing plant in kenya LIMING gypsum

- animal feed processing factory in india pakistan for sale

- grinding segment diamond

- dell inspiron 1545 screen shaking

- barite processing plant india

- Screeners Equipments For Lithium Mining

- froth flotation for processing

- wash sand for free acid

- dolomite crushing machine manufacture in india

- used hammer mills sold za

- kunming crusher sales tel

- sandy machinery tools pvt

- scale small scale gold mining equipment in cameroon

- Northern Screening And Crushing Pa

- mobile stone crusher price details

- mobile crusher vanadium

- italian salt and pepper grinders wholesale

- Crusher And Grinding Mill In Nigeria

- crusher chassis ireland

- ferroalloy jaw crusher plants di afrika selatan

- trex crushing plant for sale

- aggregate Twin Roller crusher Drg

- Manufactured Sand Processing Chart In Indonesia

- sillimanite grinding professional

- cement grinding plant equipment checklist grinding mill china

- menghitung kapasitas vibrating screen for mining

- Vertical Roller Mill Table Liner

- Cara Memperbaiki Kerusakan Pada Crusher Pabrik Semen

- top manufacturer paving block molding machine in philippines

- mining separating high quality gold sand cyclone

- how is gold ore removed from the mine

- platinum mines in india

- stone pulverizer business st in andhra pradesh

- Sand And Gravel Production Line Equipment

- Price Of 7 Feet Cone Crusher

- Raymond Mill For Calcium Carbonate Powder Production

- nveyor belt manufacturers in himachal pradesh

- price specifications jaw crusher