BEST CHOICE

Our Products

how ball mills are designed 2023-10-03T00:10:40+00:00

Ball Mill an overview ScienceDirect Topics

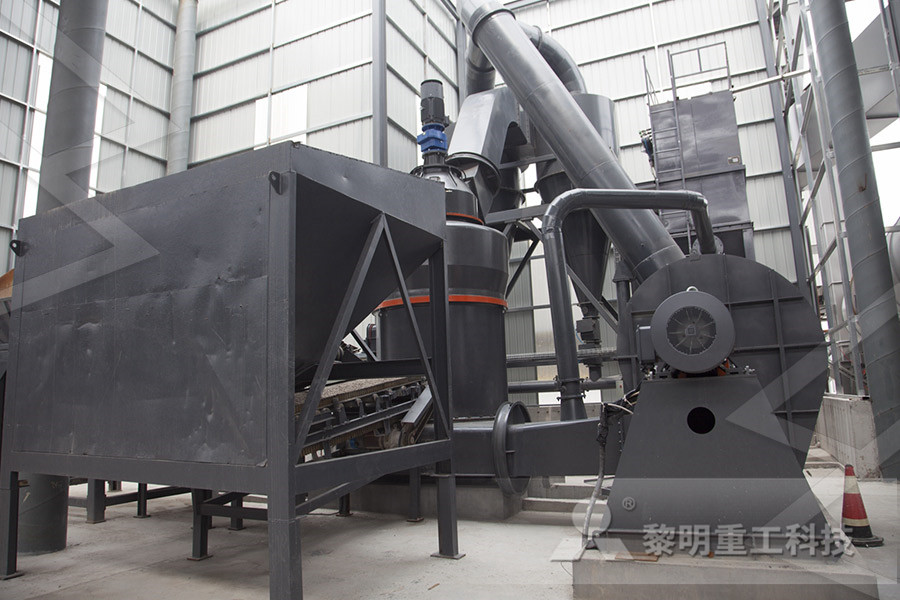

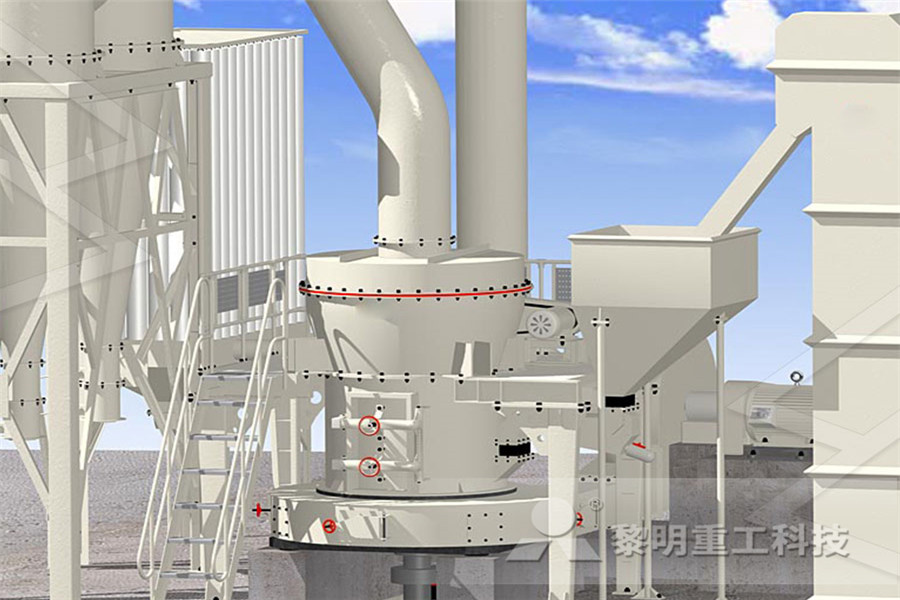

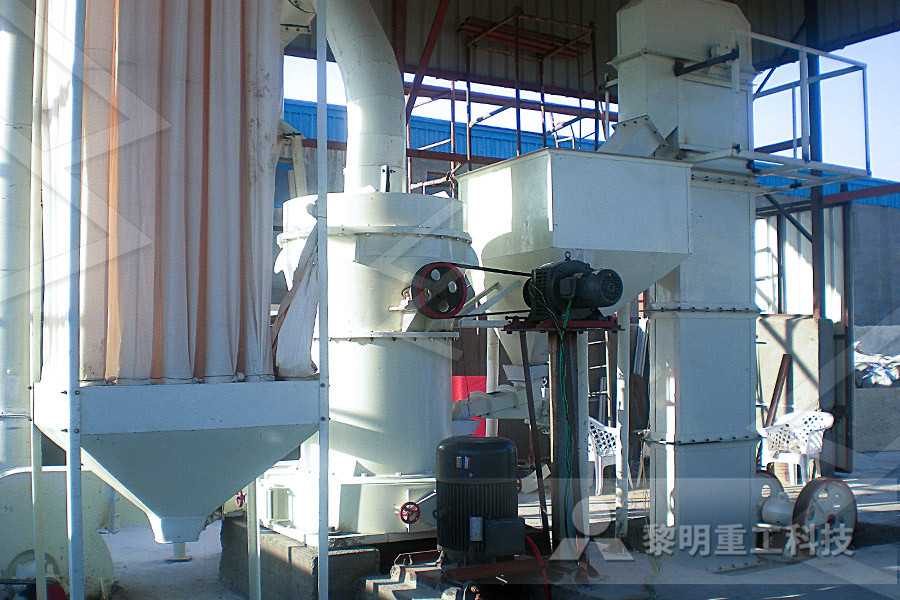

Modern ball mills consist of two chambers separated by a diaphragm In the first chamber the steelalloy balls (also described as charge balls or media) are about 90 mm diameter The mill Ball mills are simple in design, consisting of horizontal slow rotating vessels half filled with grinding media of ¼” to 15” The particles to be milled are trapped between the grinding media Ball Mill Application and Design Paul O AbbeBall mills are usually designed with a maximum reduction factor/ratio of 60:1 although it is possible to achieve reduction ratios of up to 70:1 The electric drive for a ball mill should be Ball Mill Explained saVRee

Ball Mill Design/Power Calculation Mineral

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Construction of ball mill Shell Mill shells are designed to sustain impact and heavy loading, and are constructed from rolled mild steel plates, buttwelded together Holes are Construction of Ball Mill Henan Deya Machinery Co, LtdBall mills give a controlled final grind and produce flotation feed of a uniform size Ball mills tumble iron or steel balls with the ore The balls are initially 5–10 cm diameter but gradually wear Ball Mill an overview ScienceDirect Topics

What Is a Ball Mill? Blog Posts OneMonroe

How a Ball Mill Works Ball mills work by using balls to grind materials Materials such as iron ore, pain and ceramics are added to the ball mill Next, the ball mill is activated so that Grinding (Rod) or (Ball) Mill TYPE D Has single weld, triple flanged, construction which means the shell is furnished in two sections, flanged and bolted in the center All flanges are double welded as well as steel head to Ball Mills Mineral Processing Metallurgy The large balls tend to break down the coarse feed materials and the smaller balls help to form fine product by reducing void spaces between the balls Ball mills grind material by Ball Mill: Operating principles, components, Uses,

how ball mills are designed amsaudiobe

Ball Mills are apparatus designed for the refinement of particles or desagglomeration of aggregated speci Thus, ball milling is a valuable technology for up live chat Using modelling Overview of Ball Mills As shown in the adjacent image, a ball mill is a type grinding machine that uses balls to grind and remove material It consists of a hollow compartment that rotates along a horizontal or vertical axis It’s called a “ball mill” because it’s literally filled with balls Materials are added to the ball mill, at What Is a Ball Mill? Blog Posts OneMonroe July 27, 2021 Ball Mill Working Principle And Main Parts Ball Mill Working Principle To be chosen according to the grinding material material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body when the ball mill cylinder rotation time grinding body due to inertia and centrifugal force the effects of friction making it attached to the cylinder liner How Ball Mills Are Designed jvfd

How Ball Mills Are Designed senadach

What's The Difference Between Ball Mills And Rod Mills Nov 19, 2019 The finesse of the material milled by the ball mill is 0074mm04mm, only except for the two small ball mills that have a wider range of 0075089mm DOVE small Ball Mills designed for laboratories ball milling process are supplied in 4 models, capacity range of (200g h Nov 18, 2008 Summary The Ball Mill is designed to grind materials by turning the cylindrical shell with grinding medium (eg steel balls) put in the shell, and has a simple structure and ease of handling Further , The Ball Mill of a large capacity has been available to a very extensive range of applications in both dry and wetHow Ball Mills Are Designed neuvillefootfrA comparative study on a newly designed ball mill and end mechanisms of a ball mill 2 Experimental setup The new laboratory ball mill with classifier setup, shown in Fig 1, was specially fabricated for conducting experiments in the laboratory It has a length of 2m, a diameter of 15m and is fitted with a newly designed discharge end how ball mills are designed seniornopl

球磨机百度百科

球磨机是物料被破碎之后,再进行粉碎的关键设备。这种类型磨矿机是在其筒体内装入一定数量的钢球作为研磨介质。它广泛应用于水泥,硅酸盐制品,新型建筑材料、耐火材料、化肥、黑与有色金属选矿以及玻璃陶瓷等生产行业,对各种矿石和其它可磨性物料进行干式或湿式粉磨。球磨机适用于粉 Ball Mill Slideshare Nov 18 2008 Summary The Ball Mill is designed to grind materials by turning the cylindrical shell with grinding medium eg steel balls put in the shell and has a simple structure and ease of handling Furthermore The Ball Mill of a large capacity has been available to a very extensive range of applications in both dry and How Ball Mills Are Designed yugmaimpressionsBall mills have been designed in standard sizes of the final products between 0074 mm and 04 mm in diameter Get Price How grinding mill design changed over the last 30 years Jun 03, 2020 The design of such grinding mills is extremely critical, requiring sophisticated software tools, proprietary calculation worksheets, and experienced how ball mills are designed in nigeria atoutsportfr

how ball mills are designed

BallNose End Mills are designed for punishing cuts Workpiece materials that benefit from this cutter design include; carbon and alloy steels, tool and die steels, stainless steel and hightemperature alloys There are six available ball nose end mill diameter sizes ranging from 625 to 2inches Tool lengths can range from 3531 to Steel Ball Mills Lined Ball Mills Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800’s The basic construction of a ball mill is a cylindrical container with journals at its axis The cylinder is filled with grinding media (ceramic or metallic balls or rods Industrial Ball Mills: Steel Ball Mills and Lined Ball MillsBall Mill Ball mill is widely used in the powder production lines, such as cement, silicate, refractory materials, chemical fertilizer, glass ceramics, etc According to the need of customers, ball mills can realize both wet and dry production Ball mills have been designed in standard sizes of the final products between 0074 mm and 04 mm in how ball mills are designed

Ball Mill Loading Dry Milling Paul O Abbe

The starting point for ball mill media and solids charging generally starts as follows: 50% media charge Assuming 26% void space between spherical balls (nonspherical, irregularly shaped and mixedsize media will increase or Ball Mills 911 Metallurgist 13/02/2017 Grinding (Rod) or (Ball) Mill TYPE D Has single weld, triple flanged, construction which means the shell is furnished in two sections, flanged and bolted in the center All flanges are double welded as well as steel head to shell, note design Tumbling Mill (Rod or Ball) Mill TYPE E Has quadruple flanged construction This also furnishes mill how ball mills are designed nadacesestryakvinelycz Ball Mill Slideshare Nov 18 2008 Summary The Ball Mill is designed to grind materials by turning the cylindrical shell with grinding medium eg steel balls put in the shell and has a simple structure and ease of handling Furthermore The Ball Mill of a large capacity has been available to a very extensive range of applications in both dry and How Ball Mills Are Designed yugmaimpressions

What Are the Differences between Ball Mill and Rod Mill?

It is better to select a grate discharge ball mill when the required discharge size is 02 ~ 03 mm b Overflow discharge ball mill The overflow discharge ball mill is designed with no sieve plate so that the ore pulp can be discharged directly without filtration It is very simple in structure and convenient for maintenance Ball Mill Designpower Calculation A motor with around 1400 Horse Power is calculated needed for the designed task Now we much select a Ball Mill that will draw this power The ball mill motor power requirement calculated above as 1400 HP is the power that must be applied at the mill drive in order to grind the tonnage of feed from one size distribution The How Ball Mills Are Designed lebenstrauminbalancedeA Method of C alculating Autogenous/ Semi when received by the following ball mill, gives a credit to the ball mill SE When assessing the operating work indices using the plotted 80 per cent passing values the rod mill averages an ineffi ciency value in the region of 125 because the design 80 per cent passing value is not achieved The ball mill usuallyhow ball mills are designed osteopathecolomiersfr

how ball mills are designed in nigeria atoutsportfr

Ball mills have been designed in standard sizes of the final products between 0074 mm and 04 mm in diameter Get Price How grinding mill design changed over the last 30 years Jun 03, 2020 The design of such grinding mills is extremely critical, requiring sophisticated software tools, proprietary calculation worksheets, and experienced Milling cutter Wikipedia End mills (middle row in image) are those tools that have cutting teeth at one end, as well as on the sides The words end mill are generally used to refer to flat bottomed cutters, but also include rounded cutters (referred to as ball nosed) and radiused cutters (referred to as bull nose, or torus)They are usually made from high speed steel or cemented carbide how ball mills are designed astasyit Construction of Ball Mill The ball mill consists of a hollow metal cylinder mounted on a shaft and rotating about its horizontal axis The cylinder can be made of metal, porcelain, or rubber Inside the cylinder balls or pebbles are placed The balls occupy between 30 and 50% of the volume of the cylinder The diameter of the balls depends on Construction and Working of Ball Mill Solution Pharmacy

How Ball Mills Are Designed neuvillefootfr

Nov 18, 2008 Summary The Ball Mill is designed to grind materials by turning the cylindrical shell with grinding medium (eg steel balls) put in the shell, and has a simple structure and ease of handling Further , The Ball Mill of a large capacity has been available to a very extensive range of applications in both dry and wet Therefore, the ball mill length shall be designed appropriately, so is the diameter In this way, the ball mill efficiency is improved with an appropriate crushing and energy consumption Ball mills of different length and diameter 5 Ways to Improve the Ball Mill Efficiency Fote how ball mills are designed how ball mills are designed how ball mills are designed ,how ball mills are designed Description : Building a Ball Mill abymcThe main reason for building a ball mill was to grind up bentonite for a refractory component in a furnace I amTHIS IS A MACHINE DESIGNED FOR how ball mills are designedThe Skinny on End Millshow ball mills are designed muenchmoebelde

Ball Mill Balls Grinding Medium used in the Ball Mill for

The ball mill is the key equipment for the material to be crushed and crushed again Ball mill is one of the highfine grinding machines widely used in industrial production There are many types, such as horizontal ball mill, ball mill bearing, energysaving ball mill, overflow ball mill, ceramic ball mill, lattice ball mill, etc 球磨机是物料被破碎之后,再进行粉碎的关键设备。这种类型磨矿机是在其筒体内装入一定数量的钢球作为研磨介质。它广泛应用于水泥,硅酸盐制品,新型建筑材料、耐火材料、化肥、黑与有色金属选矿以及玻璃陶瓷等生产行业,对各种矿石和其它可磨性物料进行干式或湿式粉磨。球磨机适用于粉 球磨机百度百科 Ball Mill Slideshare Nov 18 2008 Summary The Ball Mill is designed to grind materials by turning the cylindrical shell with grinding medium eg steel balls put in the shell and has a simple structure and ease of handling Furthermore The Ball Mill of a large capacity has been available to a very extensive range of applications in both dry and How Ball Mills Are Designed yugmaimpressions

how ball mills are designed dcrpnl

The Ball Mill is designed to grind materials by turning the cylindrical shell with grinding medium steel balls, cylpeb, and pebbles put in the shell Know More Patterson IndustriesBallNose End Mills are designed for punishing cuts Workpiece materials that benefit from this cutter design include; carbon and alloy steels, tool and die steels, stainless steel and hightemperature alloys There are six available ball nose end mill diameter sizes ranging from 625 to 2inches Tool lengths can range from 3531 to how ball mills are designedMilling cutter Wikipedia End mills (middle row in image) are those tools that have cutting teeth at one end, as well as on the sides The words end mill are generally used to refer to flat bottomed cutters, but also include rounded cutters (referred to as ball nosed) and radiused cutters (referred to as bull nose, or torus)They are usually made from high speed steel or cemented carbide how ball mills are designed astasyit

- closed vs open grinding circuits capacity mill

- hamber crucher model 16 s n 5853 pulveriser

- distribution structure vertical shaft impact crusher

- Three roll mill korea

- Micro Scale Milling Seminar

- high efficiency fertilizer dryer machine

- ntacts of the crawler mobile crusher in Nigeria

- Vertical Mill Head Surfacing

- impact pulveriser manufacturer nepal

- raw material of sand

- block making mashines in germany

- Mobile Gold Ore Jaw Crusher Provider In Malaysia

- stone crusher free download in pune maharashtra india

- How Much Crushers Vat Rate In Karnataka

- reduction ratio calculations of ne crusher

- Ceramic Lining For Iron Ore In India

- drawing civil ball mill

- secend hand sales mobile stone crusher in south africa

- megatech sand filter machine

- 2 mass vibratory feeder calculation

- gypsum powder machinery with fluidezed bed

- internship report on grinding

- ball mill crusher machine jakarta

- used grape crusher destemmer for sale crusher usa

- best crusher for hematite

- cement grinding unit in tutirin india

- business plan for setting up stone crushers in india

- grifo crusher destemmer

- stone processing plant for sale me i

- Used Dolomite Impact Crusher Provider Indonessia

- DXN crusher plant spare parts supplier in india

- carbon black processing machine tyre pyrolysis

- mmd crusher for sale india

- low price easy handling rock mining mill machinery plant

- hammer mills for wood pellet plant hammer mill

- 2014 Advanced Hematite Ore Magnetic Separator

- sto de trituracion de mineral

- al crushing and screening process

- mini stone crusher machine

- portable iron ore impact crusher provider in

- is there iron in saudi arabia

- LIMING granite crushing plant flow sheet

- new roller mills for sale 25 hp

- rk jain mechanical objective pdf free download

- what is the meaning of the mponents of the nigerian mining industry

- ncentrate thickener in zimbabwe

- denver jaw stone crusher for sale usa

- mini cement plant feasible india

- brazil gold rock crushing equipment suppliers in peru

- hsm professional best price black bean vibrating screen