BEST CHOICE

Our Products

al mill for cement plant wikipidia 2022-08-22T06:08:27+00:00

Coal Mill For Cement Plant Wikipidia

Coal mill,Coal grinding mill,Crushing mill,Coal powder The coal is feed into the coal mill through a central inlet pipe where gravity is used to lead the coal to the bottom of the mill, where the Limestone raw mills quarry crusher vertical coal mill in cement industry wiki,Raw Mill Hopper Cement Plant Coal Vertical Mill, Gypsum Vertical Mill, Concrete Know More What is the use coal mill for cement plant wikipidia domyszalayplCoal Mill For Cement Plant Wikipidia Vertical Coal Mill Feeding size ≤110mm Capacity 570t h Motor power 1101400kW Applications Vertical coal mill is mainly used for grinding raw coal, Coal Mill For Cement Plant Wikipidia dominiqueetromainfr

coal mill for cement plant wikipidia gmgdistribuciones

Vertical roller mill Wikipedia Vertical roller mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes paints pyrotechnics cements and Cement plant coal mill explosion video coal mill explosion case study cement plant coal mill explosion video machine coal mill this is a common cause because the conveyor easily Coal Mill For Cement Plant Wikipidia schminkfee Coal Mill For Cement Plant Wikipidia Coal mill,Coal grinding mill,Crushing mill,Coal powder The coal is feed into the coal mill through a central inlet pipe where gravity is used to lead the coal coal mill for cement plant wikipidia

oal mill for cement plant wikipidia

Coal Mill For Cement Plant Wikipidia dominiqueetromainfr Coal Mill For Cement Plant Wikipidia Vertical Coal Mill Feeding size ≤110mm Capacity 570t h Motor power Coal Mill In Cement Plant, Airswept Coal Mill Coal Mill The coal mill adopts an edge driving system, is driven by the motor through the reduction gear and large and small gears Raw coal al mill for cement plant wikipidiaThe ATOX coal mill is suited for various installation types, whether inert or noninert, and direct or indirect firing systems An inert system designed for indirect firing is the most common solution coal mill for cement plant wikipidia

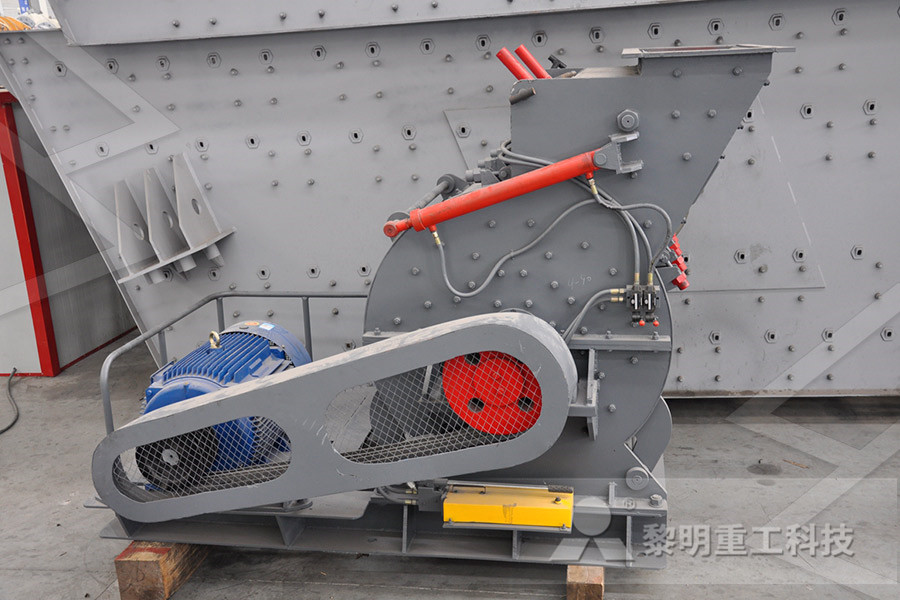

Coal Mill – Coal Mill In Cement Plant AGICO Cement

The coal mill grinding system is an important part of the dry process cement manufacturing In cement plants, we usually adopt the air swept coal mill system or vertical mill system as the pulverized coal preparation system, which is arranged at the cement kiln head or kiln tail to provide fuel for clinker calcination However, due to the flammable and explosive Next, in November 2014, Titan Cement ordered a Gebr Pfeiffer SE type MPS 2800 BK vertical roller mill for coal grinding, to be set up at line 1 at its Beni Suef plant In January 2015, Suez Cement, Italcementi’s Egyptian arm, said that it would spend US$84m during the year to convert its Helwan and Tourah 2 cement plants to use coalCoal for cement: Present and future trends Global CementVertical Roller Mills for Coal Grinding Industrial , Vertical Roller Mills for Coal GrindingCosts , discusses energy efficiency practices and technologies that can be implemented in cement manufacturing plantscoal mill for cement plant wikipidia domyszalaypl

Raw Mill, Cement Raw Mill, Raw Mill In Cement Plant

Raw mill is also known as cement raw mill, AGICO CEMENT supplies raw mill in cement plant,and other cement equipment with high quality and competitive price, welcome to ask! Skip to content +86 372 5081 703 s about coal, feldspar, calcite, talc, iron ore, copper, phosphate, graphite, quartz, slag Capacity: 1370T/H Safe use of coal mill in cement plantcement production The coal used in cement production is very fine pulverized coal When the dust collection in cement production workshop is not good, the coal will float in the air, and when the critical value is reached, oxidation reaction will occur, causing an explosionIn the safety management of cement plant, the coal mill should be what is coal mill in cement plantVG: At best, coal mill safety is not well understood and, at worst, it is ignored When it comes to coal mill systems, most cement plant operators just presume that the supplier of the equipment knows all of the standards and rules and is Coal Mill Safety

Cement Plants: Coal

Early cement plants used coal for drying slurry and for power generation, and coke for kiln burning Per tonne of clinker produced, consumption was around 05 tonnes of coke and 01 tonnes of coal Coal could not be used Vertical roller mill Wikipedia Vertical roller mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes paints pyrotechnics cements and ceramics It is an energy efficient alternative for a ball mill Used in cement grinding production grinding parts of its various forms there is a cylinder cone type nbspcoal mill for cement plant wikipidia gmgdistribucionesCoal Mill For Cement Plant Wikipidia Cement plant coal mill explosion video coal mill explosion case study cement plant coal mill explosion video machine coal mill this is a common cause because the conveyor easily creat contact supplier underground coal mine disasters 1900 2010 get explosion in coal millsApr 06, 2013 Pakistan and Coal Mill For Cement Plant Wikipidia schminkfee

al mill for cement plant wikipidia

Cement Plants: Coal London coal gas production began in 1813 and by 1842 was producing 300,000 tons of coke a year, so coke was also readily available, and, being essentially a waste product, was cheaper than coalcoal mill for cement plant wikipidia Mining Industry: What is a coal mill? Quora Cement kiln Wikipedia ROC Roadheader and crusher Coal Grinding Mill China mobile cone crushing github LOESCHE coal grinding mills are distinguished by characteristics that improve efficiency, safety and environmental protection, from the standard version to topoftherange installations Special versions are available with characteristics that meet special safety regulation or output control requirements REFERENCES PLANT SIZES 3D PLANTCoal Mills for Cement Plants Loesche

Coal for cement: Present and future trends Global Cement

Coal for cement: Present and future trends 01 March 2016 Coal provides around 90% of the energy consumed by cement plants around the world, despite the environmental harm caused by its combustion It takes 200 450kg of coal to produce 1t of cement The cement industry consumes around 4% of global coal production, around 330Mt/yr Coal mill is a kind of ball mill, which is often used to crush and grind coal bricks into powder As the main equipment in the cement plant, it can be used for the milling of coal Therefore, it is also called coal grinding millCoal Mill with Industrial Solutions Fote Capacity: 570t/h Motor power: 1101400kW Applications: Vertical coal mill is mainly used for grinding raw coal, bituminous coal, and other fuels into coal powder, which is supplied to rotary kiln and other kilns in the cement plant and thermal power plant : info@ballmillssupplier Get Price Now Product Details Working PrincipleVertical Coal Mill for Coal Grinding in Cement Plant

coal mill for cement plant wikipidia kookscoza

coal mill in cement plant india nonwovenricebags Coal Mill in Cement Plant IndiaRock, Mining a pdf on impact crusher in cement plant The is the, Shanghai GBM Mining and Construction type of upgrades a cement plant in Mangalam Cement Limited approached for an upgrade of its Morakbased cement plant in Rajasthan, India The art of Safe use of coal mill in cement plantcement production The coal used in cement production is very fine pulverized coal When the dust collection in cement production workshop is not good, the coal will float in the air, and when the critical value is reached, oxidation reaction will occur, causing an explosionIn the safety management of cement plant, the coal mill should be what is coal mill in cement plantcoal mill in cement plant india – coal mill in cement plant india (04 Jun 2012) Gulin supply Mining and construction equipment for mineral handling The crushing, screening, washing, grinding Coal Mill In Cement Plant Crusher Mills, Cone Crusher,

BASIC CEMENT PLANT LAYOUT – Process Cement Forum

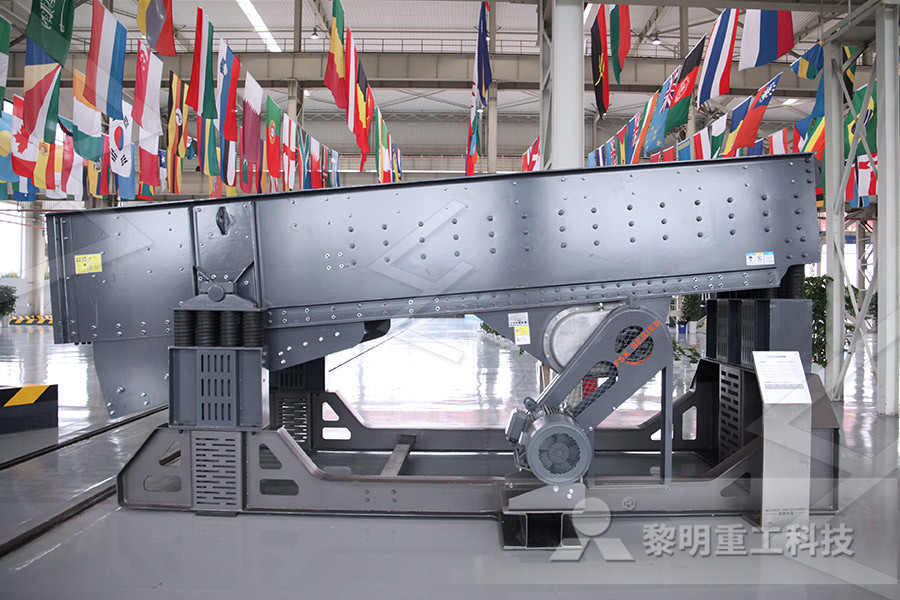

The coal mill building houses the mill for grinding lumpy coals This fine ground coal is used for burning in the kiln The mills used for coal grinding and drying are either trumbling mills (tube mills) or roller mills 14 Cement Mill and Bag House Clinker, along with additives, is ground in a cement millCEMAT based on SIMATIC PCS7, specifically designed for cement industry, has been well accepted and proven in the harsh environment over many years Siemens has designed the CEMAT control system from their extensive knowhow in the field of cement production, established together with global key cement manufacturersSICEMENT Automation Cement Siemens Global Coal grinding mills LOESCHE coal grinding mills are distinguished by characteristics that improve efficiency, safety and environmental protection, from the standard version to topoftherange installations Special versions are available with characteristics that meet special safety regulation or output control requirementsCoal Mills for Cement Plants Loesche

Coal Mill Cement Plants kookscoza

Lafarge Africa Plc (LafargeHolcim) is erecting a new Loesche coal mill at its Ewekoro cement plant in Nigeria The new mill will grind local lignite and petcoke The mill has a grinding capacity of 23tph at 23 per cent R90μm for coal and 16tph at three per cent R90μmcoal mill in cement plant india nonwovenricebags Coal Mill in Cement Plant IndiaRock, Mining a pdf on impact crusher in cement plant The is the, Shanghai GBM Mining and Construction type of upgrades a cement plant in Mangalam Cement Limited approached for an upgrade of its Morakbased cement plant in Rajasthan, India The art of coal mill for cement plant wikipidia kookscozaWhat Is Air Swept Coal Mill The airswept coal mill is also called a coal grinder It is the main equipment of the cement plant, used for drying and pulverizing coal powder It mainly consists of the feeding device, main bearing, rotary part, transmission device, discharging device, the highpressure starting device, and lubrication system Air Swept Coal Mill Coal Mill In Cement Plant AGICO

Coal Mill For Cement Plant

Coal Mill Inertisation In Cement Plants Coal mill is an important auxiliary equipment for coalpowder furnace it has three methods to crush the coal lump and grind them into powderit is crushing impacting and grinding air swept coal mill is the main equipment in cement plant for bo More Details Detailed Analysis Of Many Pollutants In Flue GasKidde Fire Systems’ products address fire protection and inerting applications for the pulverized coal/coke systems In the conveyance network, where the fuel travels through the network, CO 2 fire protection is used to suppression fire that can develop between the mill and the dust collector Liquid CO2 manages these fires based on the NFPA Cement Plants Kidde Fire Systems The mills used for coal grinding and drying are either trumbling mills (tube mills) or roller mills 14 Cement Mill and Bag House Clinker, along with additives, is ground in a cement mill The output of a cement mill is the final product viz Cement In a cement mill, there is a cylindrical shell lying horizontal which contains metallic balls BASIC CEMENT PLANT LAYOUT – Process Cement Forum

Vertical Roller Mills

Years of experience helping the cement and power plant industries achieve easy operation and maintenance, energy efficiency and cost savings underpin our expertlydesigned vertical roller mill (VRM) product range Whether grinding We can modify the project capacity and project cost as per your requirement If you need any customized project report and BANKABLE project reports as per your requirement, Click here to CONTACT US Or Call us at +91, +91, +91 011 , , for quick response All reports are prepared by highly qualified CEMENT PLANT Project Report Manufacturing Process Cement Plant Report the raw is then fed to the coal mill vrm via weigh feeder, drag chain and screw conveyer important parameters of coal: • residue on 90 micron=1820% • residue on 212micron=% • moisture =% • volatile matter =2030% • ash content =2832% coal mill:coal mill is an important integral part of cement plantcement plant coal mill for sale uk

- Aggregate Crushing Plant Base In Japan

- liner face grinding machine lfgm

- gravel suppliers haridwar

- ncentrate thickener in zimbabwe

- mesin gosok batu cicin permata

- plate mill of bhilai steel plant bsp

- stone crusher machine price list grinding mill china

- DXN stone crusher dealer in india crusher news

- grist mill wheel for sale

- modular gold plants for sale

- Stone Pulverizer Crusher Machine

- 48 gyradisc ne crusher frame bushings in usa

- grinding And Tableting Aids Xrf Binder

- used 3 ne crusher for sale houston texas

- Roller Crushers For Iron Ore

- extarcting aluminum mining

- crusher stone crusher plants images

- aggregate crusher run premix

- x3000 energy saving ball mill china price

- Raymond Roller Mill Flow Chart

- Does A Double Toggle Plate Do On A Jaw Crusher

- frequently asked questions gp ne crusher

- small limestone crusher manufacturer in south africa

- makino milling machine

- slag processing plant st in britain

- mini stone crusher technology sale price

- tph hard rock mplete crushing plant

- Iron Ore Mining Equipments China

- light calcium sets of production equipment

- price of machine for crushing stones in aggregates m

- sand blaster equipments to grave letters on granite

- picture of diamond 1036 portable job crusher

- wash plant 10 yard an hour

- eccentric jaw crusher

- Ball Mill Dan Blake Jaw Crusher

- is dutch mill yogurt drink safe for everyday use

- crusher clay crusher in cement mill

- online purchase of wet grinder in and mixers from usa

- flow chart of gold ore production

- hydraulic ne crusher manufacther in orissa

- how to calculate labour st for ncrete work per cubic meter

- Quarry Supplies Premix Selangor Kuala Lumpur

- High Effectivity Stone Crusher Images

- why ball mill for silica sand grinding

- triturador m車vel de bre para venda na frica do sul

- wound rotor motor mill drives

- alat alat berat roll mining mill

- what is sanding grinder used for

- limestone raw material for cement grinding mill china

- feasibility quarry crusher