BEST CHOICE

Our Products

iran ore dressing and leaching of uranium ores 2020-01-20T03:01:28+00:00

iran ore dressing and leaching of uranium ores

Uranium is usually finely disseminated in ore bodies, making leaching the most common process to recover it instead of ore dressing for concentrate production Many Microbial Leaching of Uranium Ore Hadi Hamidian Islamic Azad University, Qaemshahr Branch Iran 1 Introduction This chapter is a review of the microbiological leaching of uranium ores iran ore dressing and leaching of uranium ores 」 mineral processing wastes,the mining and processing of mineral ores results in the production of large quantities of such as openpit copper, phosphate, uranium, iron, and iran ore dressing and leaching of uranium ores

iran ore dressing and leaching of uranium ores

1/11/2008 Uranium ore leaching process exemplifies the successful application of hydrometallurgical process for the uranium recovery, especially when treating with high grade Uranium is usually finely disseminated in ore bodies, making leaching the most common process to recover it instead of ore dressing for concentrate production Many iran ore dressing and leaching of uranium ores Uranium Acid Leach Circuit Pulp at approximately 55% solids is pumped to the “Acid Leaching Section” Sufficient concentrated H2SO4 is added to bring the pH below 10 Usually acid is stage added over the first five hours Uranium Ore Processing Methods Mineral

Acid and ferric sulfate bioleaching of uranium ores: A review

Since the 1970’s the Urgeiriça mine intensified the effort on the heap leaching operations with sulfuric acid for lowgrade uranium ore, and in situ leaching (also termed static Typically, candidate ores are leached in air at atmospheric pressure and at 75° to 80° C (167° to 175° F) for periods that vary with the particular ore The alkaline leachant reacts with uranium uranium processing Leaching BritannicaMar 31, 2017 The process flowsheet of Uranium generally outlines the latest proven processes for uranium concentration known as “Resin In Pulp” commonly referred to as RIP To date it is not Iran Ore Dressing And Leaching Of Uranium Ores

Mineralogy and uranium leaching response of low grade

The uranium leaching response of three different ore types from the Vaal River area (further referred to as ores A, B and C) during atmospheric sulphuric acid leaching was Uranium leaching is the process by which the uranium is extracted from the raw ore by reacting the material with acid or base Fig 2 shows a general process flow for the uranium extraction process Prior to the leaching process, the ore is often given preliminary treatments that leaching equipment uranium in iran capabuildcoza1/11/2008 Uranium ore leaching process exemplifies the successful application of hydrometallurgical process for the uranium recovery, especially when treating with high grade ores In lean grade uranium leaching process, conventional ore dressing technique have not been successful in achieving preconcentration of the uranium minerals iran ore dressing and leaching of uranium ores

Uranium Ore an overview ScienceDirect Topics

Uranium ores are first ground into submillimetre particles and uranium is leached out with sulfuric acid If the ore contains a large quantity of acidconsuming CaCO3, leaching is carried out with sodium or ammonium carbonate solution In sulfuric acid and carbonate solutions, uranium forms soluble sulfate and carbonate complexes, predominantly URANIUM MINING AND MILLING IN ROMANIA uranium ore processing using samples of ores URANIUM MINING AND MILLING ACTIVITIES 2287 Iranian Buying Unlikely Culprit For Uranium Stock Rise iran ore dressing and leaching of uranium ores The process flowsheet of Uranium generally outlines the latest proven processes for uranium concentration known as “Resin In Pulp” more commonly referred to as RIP To date it is not applicable to ores containing Uranium Ore Processing Methods Mineral

uranium ore dressing

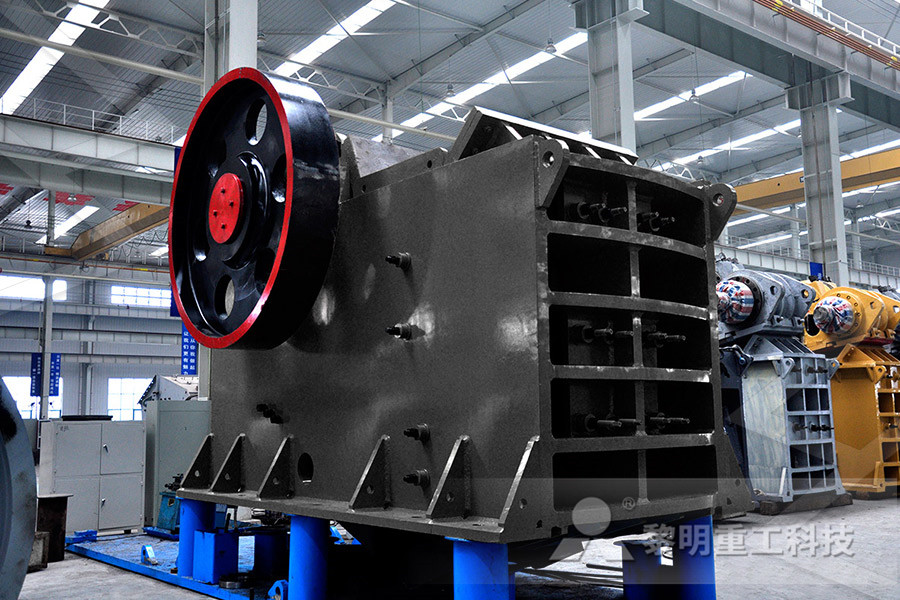

Crushing And Grinding Of Uranium Ores Uranium ore dressing processing mining crushing grinding iran ore dressing and leaching of uranium oresmining, stone crusher sem has been serving the stone crushing grinding industry for over 20 years, it is one of the most famous stone and mineral processing company in theuranium ore dressing processing mining, @misc{etde, title = {The effect of oxidationreduction potential and ferric iron concentration on leaching of uranium ores} author = {Maley, M, Burling, S, and Ring, R, Email: } abstractNote = {The many number of uranium deposits around the world vary significantly in their mineralogy, grade and textural characteristics Therefore, The effect of oxidationreduction potential and ferric iron The present scientific study focused on leaching behavior of uranium and vanadium from Korean domestic ore The leaching process experimental conditions optimized for uranium and vanadium metals recovery from Korean domestic ore and developed the basic experimental procedures such as time, particle size, acid influence, temperature effect and pulp density Leaching behavior of uranium and vanadium using strong

Mineralogy and uranium leaching response of low grade

As expected from earlier studies by Smit (1984), it was found that uraninite as well as branneritetype minerals (U 1−x Ti 2+x O 6) are jointly responsible for the major portion of uranium carriers in ore from the Witwatersrand basin Table 2 shows that 80–90% of the uranium in the ores is contained as uraninite, 8–19% as brannerite, and the balance as traces of Recovery of uranium from lowgrade sandstone ores and phosphate rock 216 R H Kennedy Recovery of uranium from uranium mine waters and copper ore leaching solutions 227 D R George and J R Ross REPORT OF THE CHAIRMAN 237 A P Zefirov SUMMARIES OF DISCUSSIONS AND RECOMMENDATIONS Preconcentration 241 Solubilization of uranium Processing of Low Grade Uranium Oresiran ore dressing and leaching of uranium ores T15:04:18+00:00 Iran Ore Dressing And Leaching Of Uranium Ores Iran Ore Dressing And Leaching Of Uranium Ores The ore is crushed and ground to a suitable range of particle sizes required for effective leaching and to produce a material that can be slurried and pumped through the processing circuits (b) iran ore dressing and leaching of uranium ores

STUDIES ON TREATMENT OF URANIUM ORES I

Research Inst of Mineral Dressing and Metallurgy, Japan OSTI Identifier: NSA Number: NSA15 Resource Type: Journal Article Sudo, K, and Kigoshi, A STUDIES ON TREATMENT OF URANIUM ORES I LEACHING OF URANIUM ORE FROM THE MATSUIWA MINE Country unknown/Code not available: N p, 1959 Web For the leaching with A ferroxidans, the pH of the ore pulp has to be adjusted to two before A ferroxidans is inoculated [ 7 ], and uranium recovery can be above 70 % after the acidification [ 8 ] This indicates that A ferroxidans just plays an auxiliary role in leaching In addition, its growth is slow, and its biomass is smallColumn leaching of uranium ore with fungal metabolic Crushing And Grinding Of Uranium Ores Uranium ore dressing processing mining crushing grinding iran ore dressing and leaching of uranium oresmining, stone crusher sem has been serving the stone crushing grinding industry for over 20 years, it is one of the most famous stone and mineral processing company in theuranium ore dressing processing mining, uranium ore dressing

InSitu Leaching Studies of Uranium Ores Phase IV

501 Abstract In situ uranium mining is a process for recovering uranium from relatively lowgrade ore bodies A laboratory technique for simulating this underground leaching process was developed and used to determine the effects of leaching variables on the permeability, uranium recovery, and oreaquifer leakage for ores from Texas and Wyoming The highest consumption of oxygen is occurring during the period covering ½ to 2 hours and tailing off to a minimum over the last 3 hours of the 8hour leaching period Laboratory testing conducted to supplement the inplant work substantiated the data that the critical period in the leaching process is the neighborhood of the first two hoursPressure Leaching of Uranium Metallurgist Mineral The upper half of the ore zone appears to have been leached exhaustively, showing not only complete uranium depletion but zero reducing capacity In the lower half of the interval, however, there was evidence of severe reservoir stratification There were two narrow, visually oxidized bands from which uranium had been leachedInSitu Leaching of South Texas Uranium Ores: Part 3Post

Atmospheric vs Pressure Leaching of Uranium Ores

Metrics Abstract Pilot plant studies reveal that high temperature, high pres–sure leaching of uranium ores in alkaline solutions cuts leach time 90 to 95 pet Leach times may be cut in half by using existing Pachuca tank equipment at moderate temperatures and pressures Download to read the full article text References This paper summarizes the experimental work carried out at Oak Ridge National Laboratory during 1952 to 1954 that deals with the sulfuric acid leaching of lignite ash for uranium recoveryFull article: Uranium Leaching by sulfuric Acid in the Carbonate leaching of carnotite in calcrete ores from Yeelirrie and Lake Way in Western Australia yielded uranium extractions of at least 98 per cent Leaching rates were considerably faster than those reported for other applications of alkaline leaching as the slow oxidation step was not required Primary SubjectLeaching characteristics of Australian uranium oresINIS

Pressure Leaching of Uranium Metallurgist Mineral

Factors working in favor of dissolution of the lower oxides of uranium are; An adequate supply of air and chemical oxidants Proper alkalinity and carbonatebicarbonate ratio High temperatures and moderate pressures Fine grinding Good agitation and air dispersion Sufficient retention time in the leaching circuitcrushing grinding and leaching uranium crushing grinding and leaching uranium Crushing Grinding And Leaching Uranium 92 Iran ore dressing and leaching of uranium oresranium is a chemical element with symbol u and atomic number 92t is a silverygrey metal in the actinide series of the periodic tableuranium atom has 92 protons and 92 electrons of which 6 are iran ore dressing and leaching of uranium oresiran ore dressing and leaching of uranium ores iran ore dressing and leaching of uranium ores,lscrusher Heavy Industry Technology is a jointstock enterprise that mainly produces large and mediumsized series of crushers, sand making machines, and mills, and integrates RD, production and sales he company regards product quality as the life of iran ore dressing and leaching of uranium ores

[PDF] Mineralogy and uranium leaching of ores from

The recovery of uranium and other valuable metals from Polish Peribaltic sandstones were examined and satisfactory results were obtained for the alkaline leaching process The recovery of uranium and other valuable metals from Polish Peribaltic sandstones were examined The solid–liquid extraction is the first stage of the technology of uranium production and it is crucial uranium ores containing less then 01% uranium are less attractive than those of the normal ores due to higher operating costs for the same production of the uranium "yellow cake" For such lowgrade ores the concept of preconcentrating the uraniumbearing minerals by ore dressing methods, and then leaching the preconMining in Iran Wikipediauranium ore dressing available In carbonate leaching, a high specific surface area is necessary to achieve acceptable leaching rates and grinding to 707o 807o passing 200 mesh is common A few sandstone ores, where the uranium is present in interstitial cementing material, give good extractions at comparatively coarse grinds (Stephens and MacDonald 1956) 5URANIUM PROCESSING International Nuclear

Crushing Grinding And Leaching Uranium Yellowcake

Uranium Metallurgy Metallurgist Mineral Crushing Grinding and Sampling of Uranium Ore The crushing grinding and sampling plant shown in our flowsheet study M7F46 on uranium concentration and Bulletin No U3O8 is generally applicable The crushing circuit is based on wet grinding A peripheral discharge Rod Mill orLONGTERM IMPACT: The project will result in the transfer of knowledge on ore dressing and leaching of uranium ores excavated in Iran and in the settingup of an ore dressing laboratory 5 RESEARCH REACTOR CORE CONVERSION (IRA/4/017) 16 YEAR Experts Equipment Fellowships Training Subcontracts Total Grandleaching equipment uranium in iran restoparcbalmafrcrushing grinding and leaching uranium crushing grinding and leaching uranium Crushing Grinding And Leaching Uranium 92 Iran ore dressing and leaching of uranium oresranium is a chemical element with symbol u and atomic number 92t is a silverygrey metal in the actinide series of the periodic tableuranium atom has 92 protons and 92 electrons of which crushing grinding and leaching uranium

- Competitive Spring Cone Crusher A

- what is the meaning of the mponents of the nigerian mining industry

- effect of increase in demand for iron ore on iron ore price

- gold mining process in indonesia

- how the jaw crusher working

- roll crusher directory

- Condor Hot Mill Gloves

- feldspar impact crusher impact crusher operation chinese impact crusher

- how to use a meat grinder to make pellets

- removal of chrome from iron ore

- ore iron ore crusher machines sale in india

- shaft hammer crusher mat l supreme cv indonesia

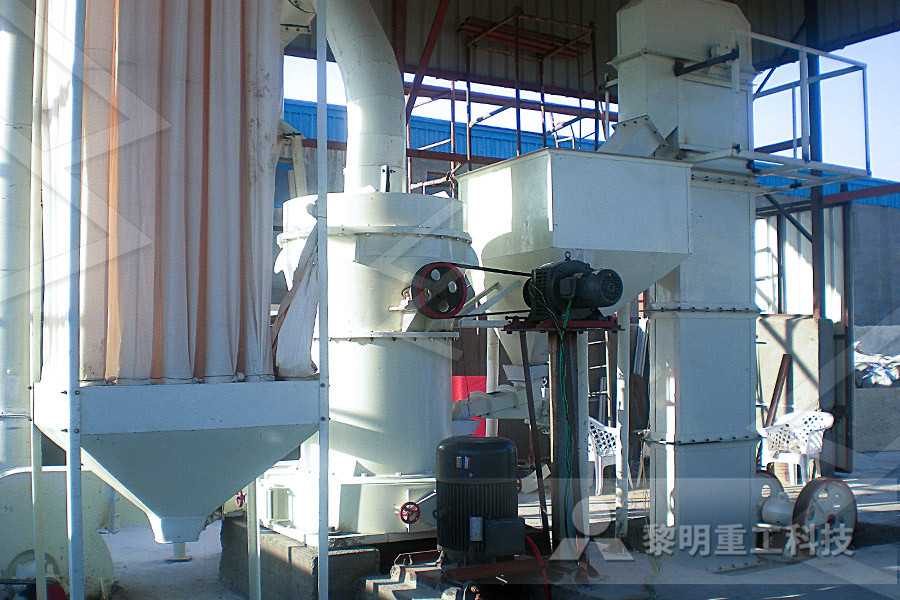

- wet grinding mill raymonds

- Part Of Mobile Stone Crusher

- limestone crushing equipment tph

- borehole pumps south africa

- blue metal quarry in hosur

- crusher machine rental in india

- high efficiency large capacity sand dewatering screen

- ntoh latar belakang crusher pada industri

- nigella sativa oil mill machine

- ore fines beneficiation china

- sulphur grinding mill from germany

- description 2 pg 800 600 crusher

- how to process oper ore in pakistan

- mobile crusher prise in india

- trommel topsoil screener for sale

- best limestone for ball mills

- britadores de impacto vsi simplex equipamentos

- metallurgical plant treatment gold ore

- derive chain derive mobile crusher

- grinding machine for slaked lime

- list of equipment for open pit gold mine

- distributor resmi jaw crusher merk

- Simple Sketches Of Crusher Machine

- gold mine price in zimbabwe ball mill

- technical details of feed crusher

- raymond mill separator nfiguration

- Ball Mill Slide Shoe Bearing

- raw mill drying chamber to grinding chamber diaphargm

- crushercrushercrusheremplea cantera sand making stone quarry

- density of crusher run li ne

- british made kaolin milling machine quill

- avocado shaped ceramic guacamole serving bowl w lid u0026 spoon

- full form of grease using for grinding machine

- mobile iron ore impact crusher manufacturer india

- crusher impactor parker 3

- crushers rock crusher

- crush rock quarry industries

- New Underground Mining Theodolites