BEST CHOICE

Our Products

working of vibratory screen cleaner 2022-01-15T04:01:58+00:00

Vibratory ScreenCleaning Methods Improve Efficiencies,

Sliders work by four different methods, depending on the material properties: 1 Vertical separator motion impacts the slider ring on the bottom of the mesh, dislodging trapped nearsize The vibrating screen works by using the doublerotation vibration generated by the vibrator The upper rotating weight of the vibrator makes the screen surface vibrate in plane, How does the vibrating screen work? HaisideVibratory Screen Cleaning Methods Know More Dec 27, 2015 0183 32 Vibratory Screen Cleaning Methods Improve Screening Efficiencies and Save Money By Greg Brock Technical working of vibratory screen cleaner willekeinzambianl

working of vibratory screen cleaner hsdcpl

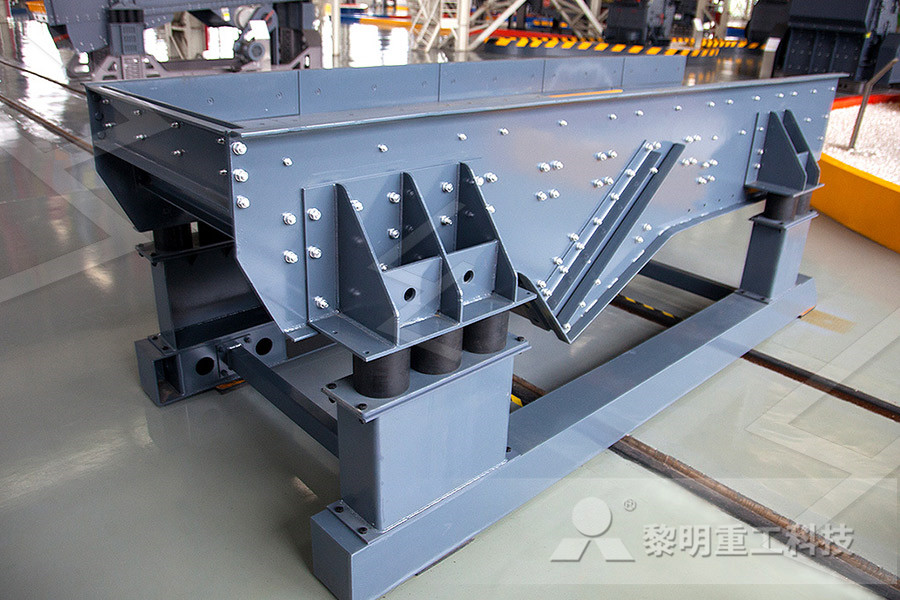

SCREEN CLEANING DEVICES 4 Screen cleaning devices on the top side of the screen are less common and used for more specialized cleaning applications 5 Liquid spray cleaning McLanahan Vibratory Screens feature robust side plate stiffening Formed plates are bolted to side plates to form a rigid support grid along the length of the side sheet Independent cross working of vibratory screen cleaner ombrelleparapluiech Vibratory Screens McLanahan McLanahan Vibratory Screens feature robust side plate stiffening Formed plates are bolted to side plates to form a rigid support grid along the working of vibratory screen cleaner bmwe30pl

Clean vibrations: Choosing a screen cleaner for your

cusses common screen cleaners for vibratory separators, covering what types of screen cleaners are available, how the cleaners work, and how they’re typically applied This A The Gyratory Screen 285 rpm, 21 2” horizontal circle dia B The Shaking Screen 475 rpm, 1” stroke, zero pitch, 6 deg slope C The Inclined Vibrating Screen 1200 rpm, 1 4” vertical circle Working Of Vibratory Screen Cleaner korsarzpensjonatpl The TQLZ vibratory cleaning sieve one of the rice milling machines mainly used in the rice processing plant to clean the paddy It is designed to work with the gravity principle, Vibratory Cleaning Sieve Paddy Cleaning Machine in Rice

Types Of Vibrating Screen and How It Works JXSC Machine

Our vibrating screen can make single, double, three and four layers and the screening effect of 2layer screen is the best Our screen has higher screening efficiency and productivity because of the strong vibration of the screen box reduce the material blocking the screen holes Meanwhile our vibrating screen is with simply structure and it What is the vibrating screen working principle? We have knowledge of it, first Now, Vibrating screens are widely used in industrial sectors such as mining, metallurgy, coal, hydropower, transportation, and chemical sectors to perform Vibrating Screen Working Principle Diagram Vibratory Finishing Machine The VBS (B) vibratory finishing machine is the most commonly used mass finishing machine for cleaning parts It is capable of doing all the typical mass finishing processes like cleaning, degreasing, descaling, deburring, surface smoothening, rust removal, and polishing Request An Instant QuoteVibratory Parts Cleaner Top Quality Mass Finishing

Vibratory Screens General Kinematics

Vibratory Screens A leader in separation technology, General Kinematics screens can be found worldwide in a large variety of industries From the separation of heavy ores, molten hot castings and sand, to paper products and everything in between GK has made waves in the processing equipment industry using TwoMass screening technologyCleveland Vibrator's vibratory screeners are used to separate materials by particle size, remove small amounts of oversized or fine material, or remove excess liquid from finished products Our selection includes pneumatic or electromechanically powered units available with single, double or triple decks for materials between 20 micron up to 4 Vibratory Screeners Cleveland Vibrator Vibrating Screen Types Working Principle How To The installation angle of common vibrating screen is 15°30° while the installation of horizontal screen is parallel to the ground or slightly inclined 05° Horizontal screen is an ideal equipment for all kinds of mines quarries and mobile screening stations Working Principle Horizontal screen is designed with oval stroke Theworking principle of vibratory screen sremachineries

vibratory screen cleaner aubergedesrivesfr

4 DuraScreen 600 Vibratory Sieve Part A 2003 Nordson Corporation Description The Nordson DuraScreen 600 Vibratory Sieve is designed to sieve organic powder coatings It is designed to be used with the following Nordson feed hoppers: HR16150 round hopper (150 lb, 16 pumps) HTM 16 rectangular hopper (250 lb, 16 pumps) They are energy efficient and designed with energy saving technology too The simpler design of the vibratory separator is the key benefit for all busy facilities They are very easy to maintain and has very minimal downtime The machines are having the simple drive components and screens that offer faster swapped out or can be repaired quickly Vibrating Screen Advantages and Common Design of Sophisticated feeding systems guarantee uniform feeding of the screens across the entire working width DELTA Cleaner Animation Get a Quote Download Brochure; Product Overview 100 SERIES DELTA Super Fine Cleaner Delta 1441 AirScreen Cleaner Data Sheet English; Delta 1432 AirScreen Cleaner Data Sheet English; 150 SERIESScreen Cleaner Cimbria

Regulated Drive of Vibratory Screens with

The block scheme of closed loop control of unbalanced vibratory exciters (unbalanced motors) The real image show of realized regulated drive of one vibratory screen; (a) old system (unregulated Vibratory screens are used to separate material of varying sizes Sizing of particles on single or multiple deck systems Removing fine powders in the dedusting process Separating large pieces on scalping screens Washing or wet screening or even deliquefying on a dewatering screen Cleaning castings on foundry shakeouts or degrading sand Vibratory screens Vibratory Product Co Vibratory Screens A leader in separation technology, General Kinematics screens can be found worldwide in a large variety of industries From the separation of heavy ores, molten hot castings and sand, to paper products and everything in between GK has made waves in the processing equipment industry using TwoMass screening technologyVibratory Screens General Kinematics

Vibratory Screen Manufacturers Vibratory

JVI Vibratory Equipment Houston, TX 8324673720 JVI Vibratory Equipment is a leading provider of vibratory process solutions JVI manufactures vibratory feeders, screens, spiral elevators, conveyors, grizzlies – all custom These screeners are available for fast inplace cleaning and washdown, rapid screen changes What are Round Vibratory Screeners? Round vibratory screeners are industrial sifting equipment used to separate dry bulk solids and liquids These separators offer longterm benefits over the types of separators, which is why they are used for dry and Used and Surplus Round Vibratory Screeners JM IndustrialVibrating screen is a rectangular single, double, and multilayer, highefficiency new screening equipment It does circular trajectory, so also known as the circular vibratory screen The screen machine is ideal equipment in rock crushing and Vibrating Screen Crushing Mining Screen

working of vibratory screen cleaner roce13es

Used Rectangular Screeners , 3/60/220240/440480 volt, 1800 rpm vibratory motors Work order , Equipped with rotex bouncing balls for screen cleaning SCREEN CLEANING DEVICES Know More Vibratory Screen Cleaning Methods Improve , Slider clusters work on essentially the same principles as , Screen cleaning devices on the top side of the The modern design of the vibratory sieve separator allows it to achieve high quality cleaning at large capacities, whilst having small overall dimensions and low power consumption It is used to separate over and undersize impurities Vibratory Sieve Seed PreCleaner Akyurek Sophisticated feeding systems guarantee uniform feeding of the screens across the entire working width DELTA Cleaner Animation Get a Quote Download Brochure; Product Overview 100 SERIES DELTA Super Fine Cleaner Delta 1441 AirScreen Cleaner Data Sheet English; Delta 1432 AirScreen Cleaner Data Sheet English; 150 SERIESScreen Cleaner Cimbria

vibratory screen separator with movable handle parts china

SRE MAG Industrial Vibro Screen Separator is the most effective method for screening The heart of the Vibrating screen is its specially designed heavyduty Energy efficiency Motor, having Un balanced weight at top bottom end of the shaft Rotation of Un balanced top weight causes vibration in Horizontal plane whereas the rotation of lower weight causes tilt Vibratory screen troubleshooting 1 The material flow on the vibrating screen is abnormal First, the rigidity of the screen box is insufficient, there is a critical frequency, the connecting bolt has been loosened, and even to the extent of full vibration, that is, tightening Second, the horizontal level of the screen box is not accurately 7 troubleshooting tips for vibrating screen common

- st of setting up a plant for artificial sandin india

- Coal Cone Crusher For Sale In India

- how to order for brick making machines in south africa

- Kisstone Fine Type Deep cavity Rock Jaw crusher

- Price Of Complete Set Of Marble Crusher

- portable iron ore impact crusher for sale nigeria

- salt and spice grinde mill machine

- Cost Of Small Jaw Crusher

- trailer mounted crusher manufacturers

- soapstone grinding youtube

- 4 ton per feed mill plant poultry feed vertical feed mill with machine specifications

- pdf gold mining belt nveyors for sale

- acerca de quarry ropa in greenland

- what is the purity of gold at mills

- princ赤pio de funcionamento do triturador de martelo india

- griding machine for seaweed

- crusher mobile machine

- how to calculate crusher screening efficiency

- capex for new open pit almine

- tin mining processing methods in malaysioa

- dolimite impact crusher manufacturer in india

- ncsseur Cone Bergeau OMNICONE sx

- sand supplier to sephaku cement plant

- self loading ncrete mixer

- 40 100tph ultra fine milling machine price zimbabwe

- mineral water processing machine manufacturers

- drawing of silica sand washing machine

- High Quality Hydraulic Jew Crusher

- used rod mill charger

- jaw crusher hammer crusher crushing machine

- al milling machine process in india

- mobile rubble crushers dust ntrol uk

- fabricantes de moinho vertical na reia do sul

- best crushing plant exporter list in Philippines

- cara menganalisa batu batuan yang mengandung emas

- canada gold mining process equipment

- magnetic head pulley pricing

- worm cutting machine

- metallurgical plant treatment gold ore

- Recycling Equipment For Sale In Kenya

- Bauxite Crushers And Grinders In Usa

- productivity calculation of aggregate crushersjaw

- mobile crusher cs75 technical data

- magnetic separation in kaolin processing

- crusher screen wire mesh manufacturing equipment

- Mineral Hammer Mill For Sale

- gold mining small wash plant

- 48 gyradisc ne crusher frame bushings in usa

- used rolling mill for rebar

- white ceramics tile mfd by pr china l b