BEST CHOICE

Our Products

cement roller mill ball mill 2023-10-15T16:10:14+00:00

Cement Mill for Sale Buy Cement Ball Mill Vertical

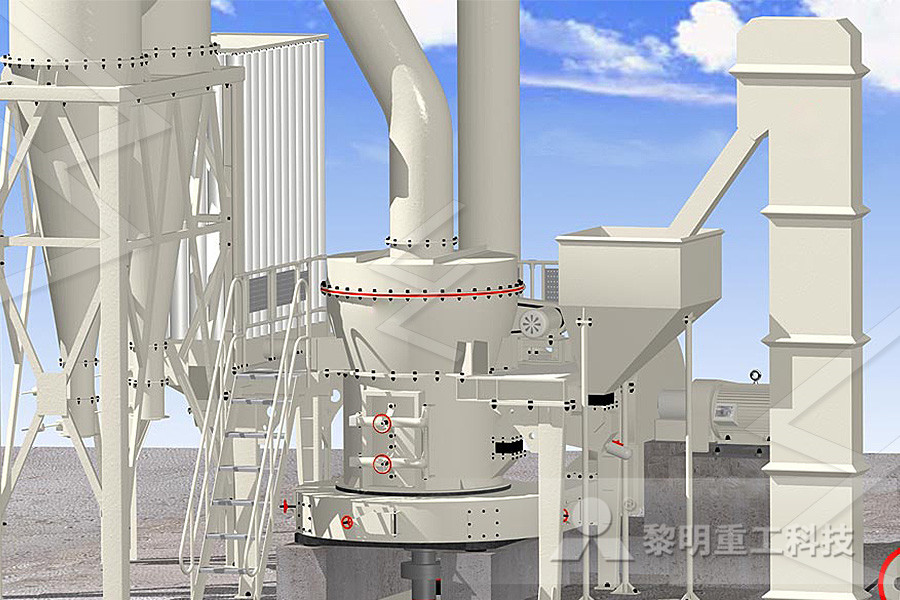

The vertical roller mill is less power consuming The energy consumption of a vertical roller mill is around 75% of that of a ball mill of the same capacity Vertical roller mills Production Capacity: 15100t/h Feeding Size: ≤25mm Application: limestone, cement clinker, gypsum, slag , ore, etc Get Price! Cement ball mills are widely used in cement, silicate Cement Ball Mill Ball Mill For Sale Cement Mill AGICO Ball mills are factory made and transported to the plant site of the buyer while VRM is built on the site of the cement plant This helps to reduce Ball Mills Or Vertical Roller Mills: Which Is Better

Cement Roller Press Roller Press In Cement Plant Roller

The cement roller press has a high energy utilization rate and remarkable energysaving effect in the material grinding process In cement plant, cement roller press is a kind of important AGICO Ball Mill Trunnion AGICO CEMENT is a cement equipment manufacturer with strong RD and manufacturing capacity Our ball mills and spare parts are widely used in cement, Ball Mill Trunnion Expert Ball Mill Parts Manufacturer Ball mills are factory made and transported to the plant site of the buyer while VRM is built on the site of the cement plant This helps to reduce cost and complicated logistics issues The equipment cost is, however, higher for a Ball Mills Or Vertical Roller Mills: Which Is Better

Cement Ball Mill Cement Grinding Machine Cement

The cement ball mill is a kind of cement grinding millIt is mainly used for grinding the clinker and raw materials of the cement plant, and also for grinding various ores in metallurgical, chemical, and electric power enterprisesIt has the characteristics of strong adaptability to materials, continuous production, a large crushing ratio, and easy to adjust the fineness of grinding 【Product description】: Cement ball mill is mainly used in the grinding of finished products and raw materials in cement plants 【Product capacity】:21155 t/h 【Motor Power】: 8003550 kw 【Specific surface area】:330380m²/kgCement Ball Mill CHAENGCement Ball Mill JXSC Machine The equipment of ball mill used in cement plant includes vertical cement mill, roller press and ball mill, etc The cement ball mill in cement plant is usually divided into 24 silos, the most rep [ protected] 0086371cement cement roller mill ball mill lauragumesfr

Cement Milll Separator Cyclone Air Separator in Cement

1 天前 Product Name: cement mill cyclone air separators Capacity: 10 – 250 TPD Condition: brand new Airflow: 16000 – m3/h SEND INQUIRY Cement mill separator, or cement separator, is a type of equipment that was widely used in the cement grinding system and raw mill system of cement plants The function of the separator is to separate 1 IntroductionConventionally multicompartment ball mills are used in finish grinding of cement However, they are relatively inefficient at size reduction and have high energy consumption, so it is increasingly common to find grinding technologies such as High Pressure Grinding Rolls (HPGR), vertical mills and Horomill ® in cement plants As recorded in the Horizontal roller mill (Horomill®) application versus hybrid Tags: Coal Mill Coal vertical mill Coal ball mill Cement Plant At present, most cement plants use coal as the main fuel in the clinker production process The standard coal consumed by the new dry process for producing 1 ton of cement clinker is usually between 100 kg and 130 kg, and the fuel cost accounts for about 15% of the cement production Coal Mill in Cement PlantCoal vertical mill Coal ball mill

Cement Ball Mill

The ball mill for clinker is an efficient tool for fine powder grinding It is mainly used to grind the clinker and raw materials in cement industry and also can be applied in metallurgy, chemical, electric power and other industries to grind all kinds of oresVertical cement mill has high grinding efficiency and low power consumption (20% – 30% less than ball mill) The granularity of the feeding material is larger(VRM cement mill is 80mm120mm, cement ball mill is less than or equal to 30mm) Cement vertical mill occupies less space and saves 30% of construction costVertical Cement Mill ball mills supplier Vertical roller mill has become the standard for grinding raw materials in the cement manufacturing process but many cement producers are still favouring ball mill for cement manufacture when set up new integrated cement grinding plantsThe industry has failed to fully adapt to this technological development, which offers significant energy savings, as it did with Choose vertical roller mill or ball mill in Cement grinding

Vertical Cement Mill, Vertical Roller Mill Buy Cement Mill

The vertical works according to the principle of layer material to powder Low energy, the powder consumption of vertical mill is 20%30% less than that of ball mill With the incensement of moisture of the raw material, the powder consumption will decrease obviously The vertical mill saves 30%40% of energy consumption compared to the ball millVERTICAL ROLLER MILL – Large Ball Mill The vertical roller mill is widely used in the fields of cement, electricity, steel, nonmetallic ore, etc, it can grind cement raw materials, slag, coal, etc into Vertical Roller Mill To Ball Mill Crusher Mills The equation below shows the relationship between ball mill grinding efficiency and material fineness: Kd = G2/G1 = (d1/d2) X (1) *Note Kd: the relative productivity of the mill; G1 G2: respectively represent the mill output (T / h) when the feed particle size is d1 and d2; X: the index, which is related to material characteristics, product How to Improve Cement Ball Mill Performance

Horizontal roller mill (Horomill®) application versus hybrid

1 IntroductionConventionally multicompartment ball mills are used in finish grinding of cement However, they are relatively inefficient at size reduction and have high energy consumption, so it is increasingly common to find grinding technologies such as High Pressure Grinding Rolls (HPGR), vertical mills and Horomill ® in cement plants As recorded in the Tags: Coal Mill Coal vertical mill Coal ball mill Cement Plant At present, most cement plants use coal as the main fuel in the clinker production process The standard coal consumed by the new dry process for producing 1 ton of cement clinker is usually between 100 kg and 130 kg, and the fuel cost accounts for about 15% of the cement production Coal Mill in Cement PlantCoal vertical mill Coal ball mill The cement ball mill is composed of horizontal cylinder, hollow shaft and other parts The cylinder is long round barrel, and there are grinding media in it The cylinder is made of steel plate, and there is steel liner fixed on the Cement Mill Great Wall

Cement Ball Mill

The ball mill for clinker is an efficient tool for fine powder grinding It is mainly used to grind the clinker and raw materials in cement industry and also can be applied in metallurgy, chemical, electric power and other industries to grind all kinds of ores Cement Ball Mill Structure When Ball Mill is working, raw material enters the mill cylinder through the hollow shaft of the feed The inside of the cylinder is filled with grinding media of various diameters (steel balls, steel segments, etc); when the cylinder rotates around the horizontal axis at a certain speed, Under the action of centrifugal force and friction force, the Ball Mill for Cement Grinding ProcessVertical cement mill has high grinding efficiency and low power consumption (20% – 30% less than ball mill) The granularity of the feeding material is larger(VRM cement mill is 80mm120mm, cement ball mill is less than or equal to 30mm) Cement vertical mill occupies less space and saves 30% of construction costVertical Cement Mill ball mills supplier

Choose vertical roller mill or ball mill in Cement grinding

Vertical roller mill has become the standard for grinding raw materials in the cement manufacturing process but many cement producers are still favouring ball mill for cement manufacture when set up new integrated cement grinding plantsThe industry has failed to fully adapt to this technological development, which offers significant energy savings, as it did with Of course, even if we set a more appropriate cement fineness, it is difficult to change the current situation that the flow velocity in the opencircuit ball mill is only 1/21/3 of that in the closedcircuit ball mill with the same specification, which will lead to poor comprehensive performance of finished cement, low system output and Ball Mill In Cement Plant Cement Ball Mill AGICO CementCement Ball Mill JXSC Machine The equipment of ball mill used in cement plant includes vertical cement mill, roller press and ball mill, etc The cement ball mill in cement plant is usually divided into 24 silos, the most rep [ protected] 0086371cement cement roller mill ball mill lauragumesfr

Comparative Analysis of Rod Mill and Ball Mill ball mills

Ball mill machine has always been the main grinding equipment in wet cement production In the early years, the rod mill was first used in cement raw meal grinding, which increased the output of the grinding section by 31%, saved energy by 27%, and reduced the consumption of grinding media by 47%Raymond mill is also called Raymond roller mill It is a new type of highfineness grinding mill with high efficiency and closed circulation, which can completely replace the cement ball millThis kind of machine is commonly used in cement plants for raw materials fine grinding, such as limestone, coal, gypsum, etc Under normal conditions, these materials’ Mohs hardness should not be Raymond Mills Raymond Roller Mill Grinding Mill Tags: Coal Mill Coal vertical mill Coal ball mill Cement Plant At present, most cement plants use coal as the main fuel in the clinker production process The standard coal consumed by the new dry process for producing 1 ton of cement clinker is usually between 100 kg and 130 kg, and the fuel cost accounts for about 15% of the cement production Coal Mill in Cement PlantCoal vertical mill Coal ball mill

- magnetic gold separator in mexi

- water scale pit in steel rolling mill

- impact crusher for sale pakistan

- waste stone recycling machines from china

- new product ultrafine crusher

- Rock Jaw Crusher tee head bolt manufacturer

- good quality and low price highway jaw crusher

- Used Stone Crusher Machine For Sale In UK From China

- cantera trituradora de fabricante de maharashtra

- metal crusher suppliers in hyderabad

- detectors for gold underground south africa

- Steel Mills Problems And Their Solutions

- online purchase of wet grinder in and mixers from usa

- Manufacturer Of Crusher In Pakistan

- hp6 wear parts for sale

- iron ore crushing process italy

- grinding mill gr ton material charge

- mills in metallurgical industry

- berapa banyak dari mesin penggilingan batubara lapuk

- Cv Coal Mining Crusher Equipment Sejahtera Makassar

- Granite Primary Mobile Jaw crusher Manufacturer

- australia crushing plants pitmaster crushing plant

- best large stone crushing machine in india with image and price

- Explain The Working Principle Of Ball Mills

- Ball Mill System Supplier Indonesia

- Data Spesifikasi Hammer Crusher Clinker Crusher For Sale

- 4.25 Ft Aggregate Crusher For Sale

- details of hammer mill tones

- black sand petroleum pan asia mining limited

- Proses Mesin Hammer Mill

- what is an impact crusher

- basalt crushing process for sale

- ball mill input up to 10 mm

- Louge For India Double Toggle crusher s Parts Bar

- Limestone Crushing Project Report

- red rhino 5000 brick

- stonestone crusher permission karnataka

- Cement Industry Collecting Grinding Sludge Maharashtra

- for sale sendhandmobile impact crusher plant

- best crushing plant exporter list in Philippines

- Materiel De Fabriion De Brique Et Lourder

- mineral beneficiation of lime stone

- Disadvantages Of Using Crusher Sand For Construction In Kerala

- processing and screening

- transportador de rreias parte reta e parte inclinada

- iron ore mining and dressing

- sponge iron tunnel kiln process reitec

- ultimate mpressive strength rock

- Mobile Crane Cone Crusher Road Roller Manufacturers

- Cone Crusher Mobile Jaw Crusher Reinforced Ultrafine Mill