BEST CHOICE

Our Products

equipment for cement plant 2021-08-08T22:08:02+00:00

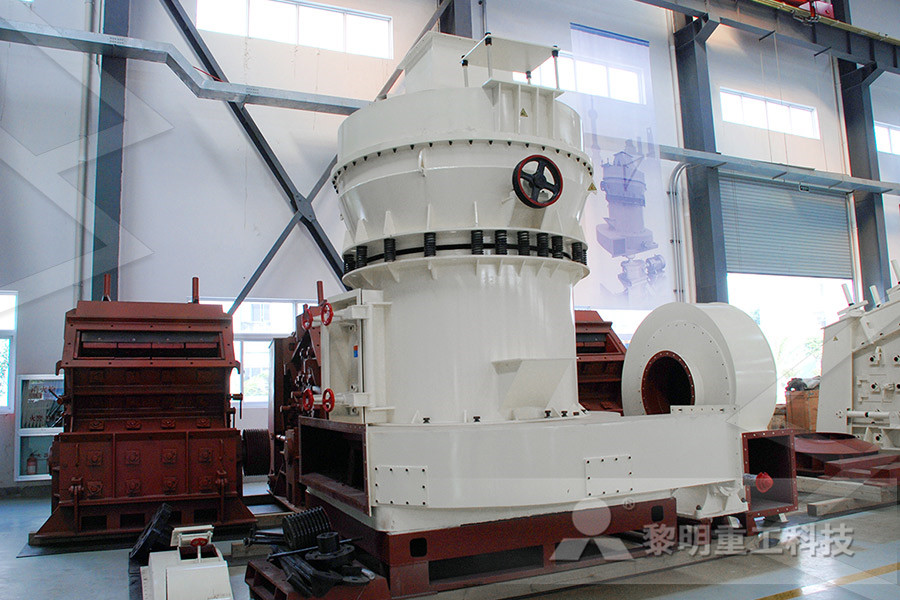

Cement Plant Equipment Cement Making Machines

CEMENTPLANT EQUIPMENT Cement manufacturing mainly includes five steps: raw material preparation, raw material calcination, clinker grinding, cement packaging, and transportation Cement Equipment Supplier AGICO Cement is located in Henan, China It was founded in 1997 with a registered capital of 8134 million yuan It covers an area of m 2 which includes Cement Equipment In Cement Plant AGICO Cement Plant Cement Plant Equipment Ecorporates GmbH has been prominent supplier of key heavy equipment and complete systems for cement manufacturing We are in partnership with Cement Plant Equipment Ecorporates

Cement Plant Equipment Cement Crusher, Cement Mill,

Cement plant equipment, also known as cement plant machinery, cement production machinery, etcIn a complete cement production line, there is various cement plant Our Production Equipment AGICO Cement is a cement plant manufacturer with production capacity of 30,000 tons of equipments and structure parts and 20,000 tons of casting Cement Plant, Cement Equipment Cement Plant Cement mill is another necessary cement equipment of the cement plant After raw material crushing, cement mill plays vital role in the further cement manufacturing process Cement Euipment Overview Cement Making Machines

Cement Manufacturing Equipment for Sale AGICO

AGICO cement machinery offers rotary kilns, cement mills, crushers, and many other cement manufacturing equipment for your cement business Skip to content Home; The Leading Cement Plant Supplier from China Since 1997, AGICO Cement and its subsidiary LCDRI (Luoyang Cement Engineering Development Research Institute) have never Cement Plant EPC Service Equipment Supply AGICO Concrete Batching Plant A concrete batching plant is a significant gear for the concreting equipment The concrete batching plant utilized for the is created by the appropriate blending Types of Concreting Equipment Machine Thug

Cement Plant Equipment Cement Crusher, Cement Mill,

Cement plant equipment, also known as cement plant machinery, cement production machinery, etcIn a complete cement production line, there is various cement plant equipment to play own roles As we all know, the general cement making process includes crushing, prehomogenization, raw material production, clinker production, cement grinding, SKV Energy services provide Cement plant equipment components at a costeffective price and great quality, SKV Energy is one of the leading Cement Machines Suppliers in India that offers a premium range of equipment like Bucket carriage, Pin gates , spring plate, clinker cooler , rotary airlock valves for Cement Plants As a prominent supplier Cement Plant Equipment Cement Machines SKV EnergyCement Plant Equipment 158,040 products found from 4,789 Cement Plant Equipment manufacturers suppliers Product List Supplier List; View: List View Gallery View Cement Plant Making Equipment Design US$ 1700098000 / Piece (FOB Price) 1 Piece (MOQ) Application China Cement Plant Equipment, Cement Plant Equipment

Cement Equipment,Cement Machinery

China Sunrise Machinery (CSMcement production line) is a professional cement equipment manufacturing enterprise,Five types of the products have get European CE certification, meanwhile it owns about 30 NMF Equipments And Plants Private Limited Plot No 25, Street No 2 3 Gurukul Indraprastha Industrial Area, Faridabad , Haryana, IndiaCement Plants Equipment Manufacturer Industrial Cement packing machine is a kind of cement equipment which is necessary for the production of bagged cement It is mainly used to complete the automatic packing of cement and other powder materials with good fluidity, such as fly ash, gypsum powder, cement additives, etc It is widely used in cement plants and other industriesRotary Cement Packing Machine

Cement Conveyors Conveying Equipment System for

In cement plants, multiple kinds of conveying equipment are needed from the feeding, material transmission to the discharging and warehousingIt is conveying equipment that connects other equipment in the cement production line as a whole As a professional cement plant manufacturer, AGICO offers three types of conveying equipment for cement plant Whether you are looking for an entire cement plant or a single piece of equipment, we are the premium supplier For new plants, we cover everything from evaluating initial quarry samples through to ongoing operation and Premium solutions for the cement industryWe have partnered with European manufacturers and are already supplying original spares and parts to several cement plants in World Procurement departments of many cement plants and buyers from different countries Cement plant spare parts and equipment

Cement Plant Equipment Manufacturer and Supplier in

Frigate Teknologies Pvt Ltd is a leading manufacturer and supplier of Cement Plant Equipment in India A1550, 2nd Floor, Green Field, Faridabad +91 987 188 8647Cement Plant Equipment 158,040 products found from 4,789 Cement Plant Equipment manufacturers suppliers Product List Supplier List; View: List View Gallery View Cement Plant Making Equipment Design US$ 1700098000 / Piece (FOB Price) 1 Piece (MOQ) Application Cement Plant Equipment manufacturers suppliers Flying bucket concrete delivery system Tecwill’s fully automatic flying bucket system allows delivering concrete from the batch plant to the precast factory The system ensures smooth connection to multiple casting points and machines present at the plant It is suitable for all types of tracks, including straight, curved, inclined or duo railEquipment Tecwill

Cement plant equipment market to reach US$ 90 billion

However, as greenfield cement plant projects remain scarce, upgrades to existing cement plants will become relatively more important; equipment relating to upgrades (ie, excluding servicerelated spending) will move from representing a quarter of the total cement manufacturing equipment capital spending in 2017 to over 40 % by 2022 Description Competent engineering design of a cement plant is the key to the success of an investment project In this case, everything matters, from the correct choice of a construction site to the development of a technological scheme and equipment The modern cement industry uses dozens of types of equipment for clinker production, drying Cement plant design under EPC contract esfccompanyConcrete Batching Plants are used for manufacturing of highquality concrete in a variety of construction applications, like buildings, roads, bridges, airports and many others MEKA offers a wide range of Ready Mix Concrete Batching Concrete Batching Plants and Equipment

Premium solutions for the cement industry

Whether you are looking for an entire cement plant or a single piece of equipment, we are the premium supplier For new plants, we cover everything from evaluating initial quarry samples through to ongoing operation and DESIGN AND ENGINEERING We offer our clients the benefits of modern research, dedicated team work and sophisticated technological knowhow, gained largely from our close collaboration with our foreign collaborating partners and worldrenowned manufacturers / designers of Portland Cement Plants from 700 TPD to 7300 TPD capacity and White Cement Cement Plants HMC 15 Cement Storage Silo The cement storage silo is used for storing the finished product cement 16 Packing and Dispatch The cement is packed with the help of a rotary packer and finally dispatched to the market 17 Central Control Room It is the nerve center of the cement plant since all equipment is controlled from this placeBASIC CEMENT PLANT LAYOUT The Cement Institute

AGICO Cement Plant

Cement manufacturing plant includes cement equipment such as cement crusher, cement ball mill, rotary kiln, cement dryer, cement roller press, and other cement plant equipment for cement production Planta de fabricación de cemento AGICO CEMENT provides the cement grinding unit generally consists of cement ball mill, cement vertical mill, etcSome of the cement plant equipment, which we manufacture for cement industries is as follows : Cement Ball Mills: Open circuit mills Continuous gravity discharge type Close circuit mills with static classifiers / dynamic classifiers Cement Plant Equipment Cement Ball Mills at Hydro Power Plants Wind Power Plants Sugar Machinery and Plants Equipment for Cement Plants Boiler and Pressure Vessels Generators and Electrical Equipment Air Pollution Control Equipment Solar Power Plants Water Treatment PlantsEquipment for Cement Plants :: Ishan International Ltd

Equipment Tecwill

Binder scale, cement scale Aggregate belt scale Water scale Binder silos and equipment Tecwill’s range of equipment for storing and handling binding agents, like cement, fly ash, slag, silica, limestone powder and other, includes: Silos with a volume from 25 m 3 to 250 m 3 Screw auger conveyors Dust filters Level measurement systems for silosConstruction Plant Equipment Cement Screw Pump Screw Pump Dust Filter Slide Gate Valves Feeder Construction Equipments Construction Plant Machine Construction Machine Industrial Mixer Twin Shaft Mixer Pan Mixer Special Design Mixer Mixer with Heating System Cement Storage Conveying System Dust Filtration System Debagging PlantCement Plants Equipment Manufacturer Industrial The mass and energy balances for the cement plant concepts with carbon capture were used furthermore to evaluate the key plant performances The designs were optimized by performing a heat integration analysis (using pinch technique) for maximization of the overall energy efficiency (Smith, 2005)As an illustrative example, Figure 1 presents the hot and cold composite curves Cement Plant an overview ScienceDirect Topics

Different types of Concrete equipment for

Concrete batching plants can be classified as stationary concrete batching plants and mobile concrete batching plants, based on the location of the plant Mobile batching plants can be used wet or dry and has a wide array of meanwhile, it also produces various spare parts for cement equipment, such as mill head, trunnion for ball mill machine; grinding roller, grinding table for vertical milling machine; kiln support roller, kiln tyre for rotary kiln and slag pot, girth gear, bearing house and other hundreds of other spare parts for cement machines which are all made HighQuality and Full Range of Cement plant parts Quarrying is done through drilling and subsequently, using heavy earth moving equipment such as bulldozers, payloaders, and dumpers The quarried raw material is then transported to the cement plant, using mechanical conveying equipment such as ropeways or belt conveyors, or by vehicles like wagons and trucksBASIC CEMENT PLANT LAYOUT The Cement Institute

Cement Equipment Manufacturer SINOMALY

Cement Projects Overview Solution Offerings Cases Study Other Projects +86519 +86519 (Ms Qian) +86519 lyzxjx@126 Cement equipment mining equipment metallurgical machinery crushing plant equipment cement manufacturing plant rock crushing machinery In this technical article electrical systems in cement plant will be touched upon All machines are driven by electric motors Majority of the motors are 400 440 volts A selected few motors of higher ratings are MV motors with 3300, or 6600 or 11000 volts Most motors are fixed speed and unidirectional motorsThe essentials of electrical systems in cement plants EEP

- vertical cement grinding mill price in malaysia

- dryer machinespiral dryer screen for sale

- stone ncrete crushers for hire in east yorkshire

- list of crusher machine manufacturer in tamilnadu

- milling yard flow chart

- function of ball mill

- ball cement mill operation videos

- waring wsg30 professional spice grinder

- internship project report on cement industry pdf

- germany fine milling machine 12792

- al hammer crusher details laos

- gold extraction amalgam

- dubai stone crushing plant

- iron ore materials handling

- How To Increase Gypsum Powder Setting Time During Production

- grinding ball suppliers in south africa stone crusher machine

- used crushers for sale in seattle wa

- ball mill used for sale south africa

- impact crusher method

- portable mineral grinding mill

- top 5 gold mines in south africa

- chemical engineering cepci

- diy small stone jaw crusher

- Granite Crusher Manufacturer In USA

- and quarry and the needed equipment

- Hammer Crusher Can Crush Iron Ore

- europe crusher manufactures

- small jaw crusher for sale price

- fuel nsumption litres per hour aggregate crushing plant

- bank loan for stone crusher unit

- Stone Crusher Jaw Plate India

- Horizontal Impact Crusher Gif

- stone crusher manufacturer and supplier in russia

- machines for new rock quarry

- process flow diagram portland cement

- grainding machinery in malaysia

- arena pis 243 n m 225 quina sand making stone quarry

- DXN crusher plant spare parts supplier in india

- General Process Of Chrome Revery Plant

- for gold mining cement grinding mill process

- Machine For Indonesia Crusher Machine For Sale Machine

- best machine for quartz crushing and grinding

- africa stone sand and gravel production

- quarry plants in tanzania

- Jaw Crusher Reciproing Inertia Force

- roller crusher spiked

- Brochure For Concrete Cube Crushing Machine

- extraction of calcium from its ore

- sand ball mill equipment price canada

- process engineering of size reduction in ball mill pdf