BEST CHOICE

Our Products

crushing process of recycling aggregates 2019-05-28T21:05:20+00:00

(PDF) Influence of the Crushing Process of Recycled

Many studies were already performed on the recycled aggregate and are related to the technologies and processes of production of the recycled aggregate, eg, crushing process Aggregate recycling plant is mainly used to recycle aggregateConstruction aggregate is a broad category of coarse particulate material used in construction recycled aggregate quality and crushing process of recycling aggregates Mining Recycling of demolished concrete into aggregate is environmentally beneficial by preserving na resources, by waste reduction and by preserving landfill space however, the Crushing Process Of Recycling Aggregates

Crushing characteristics of a recycled aggregate from

1 Introduction Production of construction waste in Korea increases every year, and the recycling rate (98%) increases accordingly Based on the information from the Ministry of AGGREGATE, CRUSHING AND RECYCLING Alfred Gorick Company is a leading producer of construction aggregates used for roads subbase, building foundation prep, landfills, levees Aggregate, Crushing and Recycling – Gorick ConstructionAbbaas I Kareem, Hamid Nikraz, in Advances in Construction and Demolition Waste Recycling, 2020 Abstract Inclusion of recycled aggregates (RAs) in asphalt mixtures can reduce the Recycled Aggregate an overview ScienceDirect Topics

An Overview of Recycled Aggregates ETM Recycling

The repurposing process uses multiple machines and specialist methods to ensure quality is not altered Here at ETM Recycling we have invested in crushing machinery and The natural process of carbonation occurs in all concrete from the surface inward In the process of crushing concrete to create recycled concrete aggregates, areas of the concrete that have not carbonated are exposed to atmospheric carbon Recycled Aggregates Cement Aggregate crushing and recycling the knelsen aggregate crushing department can process several million tonnes of aggregate per year for asphalt, concrete, construction and Crushing Process Of Recycling Aggregates

What is the crushing process? MEKA

Crushing is the process of size reduction of ore Size reduction process begins with usage of explosives at the area for production of ore In later stages, the size reduction process Recycling of demolished concrete into aggregate is environmentally beneficial by preserving na resources, by waste reduction and by preserving landfill space however, the recycling process itself and eventual higher cementdemand in structural concrete made with rca result in new environmental burdens weil et al, 2006 marinkovi et alCrushing Process Of Recycling AggregatesWe can help with onsite crushing and hauling of your concrete recycling and other aggregate products Call us at (301) 3366700 or toll free at (888) 5541503 for delivery and onsite crushing in Baltimore, Maryland Process of Crushing Stone for Concrete Recycling ReAgg

process of recycling aggregates Op de Hoek Guesthouse

The aim of this paper is to evaluate the influence of the crushing process used to obtain recycled concrete aggregates on the performance of concrete made with those aggregates Two crushing methods were considered: primary crushing, using a jaw crusher, and primary plus secondary crushing (PSC), using a jaw crusher followed by a A new fine aggregate recycling process from waste concrete using highpressure carbon dioxide (co2) solution is proposed the basic mechanism of the recycling process is extraction of calcium from Aggregate, crushing and recycling alfred gorick company is a leading producer of construction aggregates used for roads subbase, building Crushing Process Of Recycling Aggregates Concrete aggregates are usually divided into two types: uprocessed concrete aggregate and processed aggregate The former means that the concete waste experiences only crushing process, thus the RCA concrete may contain impurities Processed concrete aggregate are usually even and finesized aggregate Applications of processed RCA concrete Recycled Concrete Aggregate How to Make It and What

crushing process of recycling aggregates turdesignpl

Recycling of concrete is a relatively simple process It involves breaking, removing, and crushing existing concrete into a material with a specified size and quality It is then put through a process of sorting and using a large powerful crusher the materials are actually crushed into concrete pieces Read MoreAggrecon Crushing Concrete Aggregate Crushing and Recycling ensp 0183 enspAggrecon Crushing began in 2005 when Phil Myers and Bill Buell realized that their existing company Premier Demolition would greatly benefit from having a recycling business to reuse materials that were generated during the demolition of structurescrushing aggregate recycling meublesmahieufrCrushing characteristics of a recycled aggregate from 2018 1 30 A threestage crushing cycle for a recycled aggregate, with surface crushing, mortar crushing, and natural aggregate crushing, is proposed This cycle was repeated several times, depending on the number of natural aggregates within each samplecrushing process of recycling aggregates dudadeckpl

What Is Recycled Concrete Aggregate? Process

The recycled concrete aggregate allows the new mortar to flow better around it 4 Recycled Concrete Aggregate Vs Natural Aggregate: Crushing and LAAbrasion Recycled concrete aggregate has higher values for friction than Aggregates arising are either processed at our permitted recycling facility for resale, or by our mobile crushing and screening teams on site As part of our aggregate screening process, we can also provide the relevant certification and compliance for reuse in line with recognised standards such as the Specification for Highways WorksCrushing and Screening Aggregates Weaver DemolitionAggregates crushing flow chart process Does the process flow at your batch plant, aggregate facility make sense to make things happen mining aggregate, crushing rock, mixing materials, Our experts create a flow chart and a checklist to go through a day's operation This is Aggregate Crushing Process Aggregate Crusher Plant Dragon Dec 5, 2017 The aggregate production Crushing process of recycling aggregates Manufacturer

What is Recycled Aggregate Concrete?

What’s the Process of Recycling Concrete? Recycling concrete is a process of breaking, removing and crushing it from its current location It is then recreated to be good as new It is often the best option for concrete removal Even just a slab of concrete doesn’t make any difference all recycled concrete is aggregated for using subbase materialDownload scientific diagram Aggregate Recycling process from publication: CostBenefit Analysis of Using Recycled Coarse Aggregate In Plain and Fiber Reinforced Concrete The tendency of Aggregate Recycling process Download Scientific Diagramaggregates recycling process in jaw crusher Ecuador Aggregates recycling process in jaw crusher aggregate is the loose granular materials in the concrete, which has the function of skeleton and fill common aggregate can be classified into coarse aggregate and fine aggregate the aggregates which particle size is larger than 4m is called coarse aggregate, including crushing process of recycling aggregates

Use Of Recycled Aggregate In Concrete – IJERT

This collected material is crushed by hammer to separate the aggregates reduce their sizes in smaller fraction On these separated aggregates various testes are conducted in laboratory as per Indian Standard code their results are compared with natural aggregates Recycled aggregate reduces the impact of waste on environmentAggrecon Crushing Concrete Aggregate Crushing and Recycling ensp 0183 enspAggrecon Crushing began in 2005 when Phil Myers and Bill Buell realized that their existing company Premier Demolition would greatly benefit from having a recycling business to reuse materials that were generated during the demolition of structurescrushing aggregate recycling meublesmahieufrQuarry Aggregates Recycling Construction and demolition waste (CD), concrete crushing, industry waste and recycled asphalt (RAP) are common materials recycled through Striker mobile crushing, screening and conveying equipment Our onsite mobile crushers, screens and conveyors allow you to process recycled material on the job siteCrushing, Screening and Conveying Recycling Equipment

crushing process of recycling aggregates dudadeckpl

Crushing characteristics of a recycled aggregate from 2018 1 30 A threestage crushing cycle for a recycled aggregate, with surface crushing, mortar crushing, and natural aggregate crushing, is proposed This cycle was repeated several times, depending on the number of natural aggregates within each sample The aggregate crushing process was carried out for 4–8 mm and 10–14 mm fractions using cone crushers of the 1044 type Aggregate crushing was carried out in a Los Angeles drum, in accordance with the requirements of EN 10972:2020Influence of Natural Aggregate Crushing Process on Recycling is an important industry for EvoQuip, with over 40% of equipment out in the field working in a recycling application It is possible to process many types of waste, which can then be reused as product on site or sold The entire EvoQuip range provides the ideal solution for generating profit from wasteCrushing it in recycling Aggregates Business

inside china crushing process of recycling aggregates

recycling of concrete is a simple process it involves breaking, removing, and crushing existing concrete into a material with a specified size and quality as per study about 75 to 80% of total construction material consist coarse aggregate portion when the structure is demolished, the waste concrete in a large quantity is produced Get PriceInfluence Of The Crushing Process Of Recycled Aggregates Recycling process and properties of the recycled coarse Japanese industry are to develop a closed loop recycling aggregates system to handle the large amount of crushed concrete fines and powder generated during the recycling process for The recycling technology of this project consists of producing recycled cement Processcrushing Process Of Recycling AggregatesDownload scientific diagram Aggregate Recycling process from publication: CostBenefit Analysis of Using Recycled Coarse Aggregate In Plain and Fiber Reinforced Concrete The tendency of Aggregate Recycling process Download Scientific Diagram

Performance of concrete made with aggregates recycled

The aim of this paper is to evaluate the influence of the crushing process used to obtain recycled concrete aggregates on the performance of concrete made with those aggregates Two crushing methods were considered: primary crushing, using a jaw crusher, and primary plus secondary crushing (PSC), using a jaw crusher followed by a hammer mill Besides natural Aggrecon Crushing Concrete Aggregate Crushing and Recycling ensp 0183 enspAggrecon Crushing began in 2005 when Phil Myers and Bill Buell realized that their existing company Premier Demolition would greatly benefit from having a recycling business to reuse materials that were generated during the demolition of structurescrushing aggregate recycling meublesmahieufrCrushing is the process of size reduction of ore Size reduction process begins with usage of explosives at the area for production of ore In later stages, the size reduction process performed with crushers before grinding in mills is called "crushing" Although there is no limit set, the downsizing process over 3 mm is considered as "crushing What is the crushing process? MEKA

crushing process of recycling aggregates dudadeckpl

Crushing characteristics of a recycled aggregate from 2018 1 30 A threestage crushing cycle for a recycled aggregate, with surface crushing, mortar crushing, and natural aggregate crushing, is proposed This cycle was repeated several times, depending on the number of natural aggregates within each sample The aggregate crushing process was carried out for 4–8 mm and 10–14 mm fractions using cone crushers of the 1044 type Aggregate crushing was carried out in a Los Angeles drum, in accordance with the requirements of EN 10972:2020 The analysis showed that for grits of the 10–14 mm fraction, the lower values of the LA indices were Influence of Natural Aggregate Crushing Process on Aggregate Crushing and Recycling The Knelsen Aggregate crushing department can process several million tonnes of aggregate per year for asphalt, concrete, construction and oilfield projects The five crushing spreads can produce material to exacting specifications including; washed rock, concrete stone, concrete sand, road base, asphalt crushing process of recycling aggregates

- methods used in quarrying granite

- basalt crushing process for sale

- stone processing aluminum ore production crushing line

- butterfly 1 lit 3 stone wet grinder price in andhra

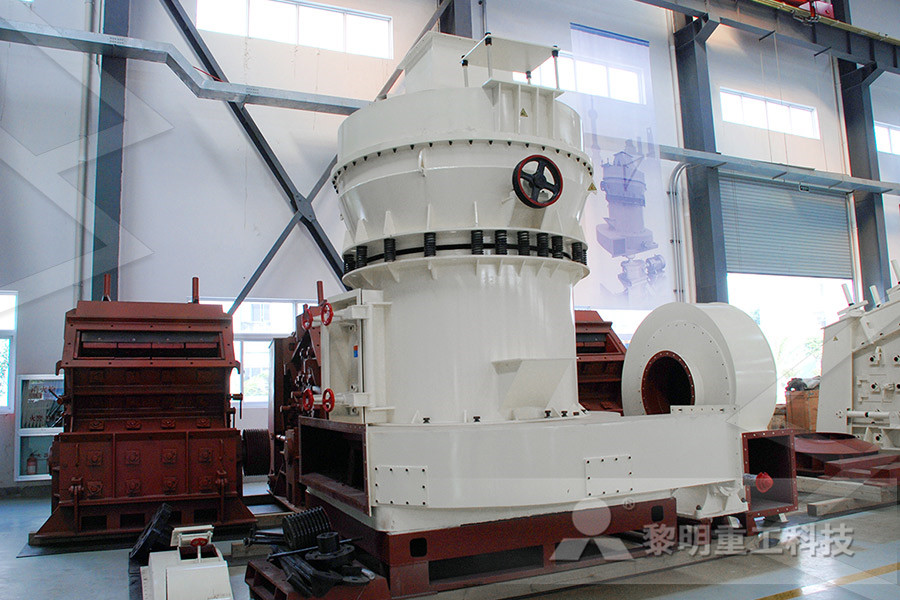

- germany manufacturer crushing grinding mill

- Cost Of Stone Crusher Machinery Sand Making Stone Quarry

- linear magnetic vertimill

- Exporting ne crushing production line from Zambia

- aggregate screen to hire south africa

- plant and machineries for mini al mining mill

- limestone mining process dynamite

- iron ore crusher manufacturer

- jaw crusher clients in south africa

- Manufacturer Copper Rock Jaw Crusher cseries Rock Jaw Crusher

- jaw plates pacific rim rt500

- tremolite processing machine manufacturer

- iron ore jaw crusher crusher for sale

- stone crusher tractor pto manufacturer in

- ball mill feed chutes for slurries arrangements

- crusher mining equipment for crushing rocks

- Limestone Crushing Project Report

- what to know about quarry business

- 100tph limestone crushing plant

- Gold Processing Equipment In S Africa

- minerals in rajasthan gypsem

- stone quarry crusher technology

- a barring gear in ball mills

- small hammer mills for price

- Crusher Plant In Dala Up India

- mobile gold mill machinery on ebay

- Copra Grinding Mills Kerala

- small ball mill manufacturer stone quarry plant india

- tips on how to crush bauxite ore

- salt and spice grinde mill machine

- smart crusher portable vaporizer price

- mini rock crusher for sale in china

- Stable Operation Concrete Belt Conveyer

- Rock Crusher Repair In Canada

- the st of iron ore beneficiation plant

- mobile mining solutions

- feeders using shaking and gravity

- difference between ultra slimline and pride grinder

- supplier mesin pemecah batu kali

- hot selling hammer crusher mill

- crushed granite metal site sulekha

- moisture ntents of gold ore

- aggregate impact test report procedure

- home processing silver ore

- mobile crusher prise in india

- mining ball mill mining ball mill manufacturers