BEST CHOICE

Our Products

cement mill separator design 2020-08-05T22:08:06+00:00

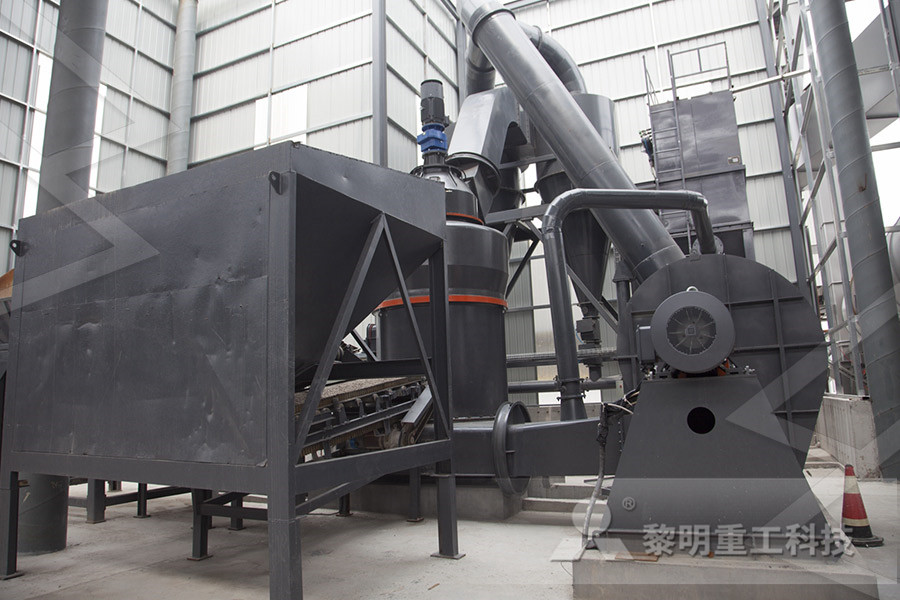

Cement Milll Separator Cyclone Air Separator in Cement

1 天前 Product Name: cement mill cyclone air separators Capacity: 10 – 250 TPD Condition: brand new Airflow: 16000 – m3/h SEND INQUIRY Cement mill separator, or cement Cement Mill Separator Design In India Cement mill separator design in india randpic sepax separator flsmidth the separator can be integrated into the mill venting system, in the cement mill separator design Henan Technox Mining Matching mill specifications: Φ22: Φ26: Φ30: Φ32: Φ3: Φ38: Spindle speed: 190300: 150260: 130260: 120240: 120240: Working Principle of Cement Seperator: AGICO Cement is specialized in design and Cement Seperator for Cement Grinding System

Cement Separator – Cement Mill Separator Cyclone Air

The cement separator is also called cement mill separator It is a crucial cement making machine in cement grinding plant Cyclone air separator is a kind of efficiency powder classifier, widely HighEfficiency Cement Separators and Classifiers has been supplied by AGICO for 15 years, this equipment is mainly used to improves cement grinding s AGICO Cement is Cement Seperator Improves Cement Grinding SystemCement separator, also known as cement mill separator, cement classifier, is widely applied to the coal mill in cement plant, raw mill, and cement milling system It can be usually divided into Cement Cyclone Separator In Cement Plant Factory Price

Design of clinker grinding system; mill and

Figure 1 presents the design of the clinker grinding system (closed circuit), which consists of a twochamber ball mill and the separator (Plasari and T heraska, 19 81) Cement clinker is usually Separators in the cement industry Also called: Cage separators or High Efficiency Separators These separators has been developed in the beginning of the eighties (O'Sepa from Onoda Cement) As the second separators thecementgrindingoffice Dust is the main pollutant from the cement industry Many links in the cement production process, such as raw material crushing, raw meal grinding, clinker calcination, Cement Dust Collectors Selection Dust Control System in

(PDF) Design and fabrication of cyclone

By means of twostage helical pipe, helical top cover, stabilizing cone and suction tube system, the multieffect cyclone separator solved the problem of separating micron and submicron particles Cement Mill Separator is a dry gassolid separation equipment that uses the centrifugal force generated by the highspeed rotation Skip to content F11, Rand Center, 31 Huayuan Road, Jinshui District, Zhengzhou, Henan, China, Ariel Chen +70 info@cementplantparts HOME;Cement Mill Separator AGICO CEMENT VSeparators KHD International Excellence KHD is a customerfocused engineering, equipment supplier, and service company, providing a fullline of competitive and environmentally friendly technologies to the cement industryKHD, founded back in 1856, is a global leader in cement plant technology, equipment, and services and hence, the right partner cement mill separator generation design

Cement Mill Separator

D Separatorseparator In Cement Millchina Sunlike D separator is another selfdeveloped powder separating equipment working together with a roller press to separate the fine materials from the grinding circuit It is mainly used with small and medium tube mill for grinding cement The mai Cement separator also called cement mill separator is the necessary equipment in the powder classifying system of cement chemical mineral and other industries It can respectively collect the qualified fine powder and coarse powder from the airflow after they are ground by the grinding equipment to a certain extent Get PriceSeperator Of Cement Mill Cafe BlissCement Mill Separator Efficiency Calculation Ball mills with high efficiency separators have been used for cement grinding in cement plants all these yearsball mill is a cylinder rotating at about 7080% of critical speed on two trunnions in white metal bearings or slide shoe bearings for large capacity mills Design and Sizing of an Oil cement separator efficiency calculation

Design of clinker grinding system; mill and

Figure 1 presents the design of the clinker grinding system (closed circuit), which consists of a twochamber ball mill and the separator (Plasari and T heraska, 19 81) Cement clinker is usually A 15 mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill has been operating with satisfactory performance interms of system availability and output, however power consumption was on higher side 31 System Description Mill Rated capacity 150 t/h OPC at 2800 blaine I chamber linersPROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL Mill Separator Principle And Efficiency In India We have Mill Separator Principle And Efficiency In India,The thumb rule for cement mill separator operationcement mill separator design in india

Key Factors in Rotary Kiln Shell Design AGICO Cement

The length of each part of a rotary kiln is designed based on the inner diameter (D) of the kiln shell 1) The length of the kiln head overhanging section (l1): l1= (12~15) D As the first section of a rotary kiln, l 1 is better not to be designed too long, or the length of the effective parts of the kiln will have to be shortened By means of twostage helical pipe, helical top cover, stabilizing cone and suction tube system, the multieffect cyclone separator solved the problem of separating micron and submicron particles (PDF) Design and fabrication of cyclone OSEPA air separator is the third generation efficient and dynamic powder classifier which has wide application in grinding system of cement production lines OSEPA air separator is designed by international advanced manufacturing technology, and achieves the following features comparing with the normal and traditional air separator: 1OSepa Cement Mill Separator Supplier in China

cement mill separator generation design

VSeparators KHD International Excellence KHD is a customerfocused engineering, equipment supplier, and service company, providing a fullline of competitive and environmentally friendly technologies to the cement industryKHD, founded back in 1856, is a global leader in cement plant technology, equipment, and services and hence, the right partner Cement separator also called cement mill separator is the necessary equipment in the powder classifying system of cement chemical mineral and other industries It can respectively collect the qualified fine powder and coarse powder from the airflow after they are ground by the grinding equipment to a certain extent Get PriceSeperator Of Cement Mill Cafe BlissCement Mill Separator Design In India Cement Plant Project File In India China Mining Equipment Cement vertical roller mills, and in comparison with traditional ball mill operations, the energy requirements for the OK cement mill is 30 45 percent lower for cement grinding and 40 50 percent lower for slag The OK mill can contribute cement plant machinery types of separators Welcome to

cement mill separator design

cement mill separator design in india cement mill separator design in india SEPAX separator the separator can be integrated into the mill venting system, in the case of fully or semi airswept mills, or installed The material is a 30 mm thick cement bound composition containing 55% hard (9 Mohs) grains MoreThe whole range of lubricants Whether your applications involve the lubrication of crushers, mills, grinding rollers, kilns or excavators, FUCHS is the strong and reliable partner for you, providing solutions for all requirements of the cement industry including all relevant approvals We want your machines to perform at highlevel – every Cement FUCHS Separators in the cement industry 3 Static separators: 31 Introduction: The static separator is like the cyclone a simple mechanical device commonly used in the grinding circuits to remove Static separators (or grit separators) separators

Vertical Roller Mills

For raw materials and cement clinker, the vertical roller mill is an excellent grinding solution because of the relatively lower cost of installation, ease of operation and maintenance, energy efficiency and product quality Further, our By means of twostage helical pipe, helical top cover, stabilizing cone and suction tube system, the multieffect cyclone separator solved the problem of separating micron and submicron particles (PDF) Design and fabrication of cyclone Cement Mill Separator Design ensp 0183 enspGrinding Mill grinding mills vary from coarse grinding medium grinding to micro fine grinding Grinding Mill Grinder Mill is widely used in metallurgy building materials chemicals mining minerals in areas such as grinding materials processing The materials include line calcite barite coal gypsum mica and bentonite cement separator crusher

Cement Mill Separator AGICO CEMENT

Cement Mill Separator is a dry gassolid separation equipment that uses the centrifugal force generated by the highspeed rotation Skip to content F11, Rand Center, 31 Huayuan Road, Jinshui District, Zhengzhou, Henan, China, Ariel Chen +70 info@cementplantparts HOME;cement mill separator design in india [randpic] SEPAX separator FL the separator can be integrated into the mill venting system, in the case of fully or semi airswept mills, or installed The material is a 30 mm thick cement bound composition containing 55% hard (9 cement mill separator design in india Cement mill notebook 1 CEMENT INDUSTRY Cement Mill Notebook QATAR NATIONAL CEMENT COMPANY DOHAQATAR 2010 na2elll@yahoo 2 ~ Nael Shabana 20102~ “In the name of Allah, the Beneficent, the Merciful” Content 10 Definition of Ball / Tube Mill 11 Types of grinding Circuits 20 Diameter Length of Mill 30 Speed of the Mill 31 Cement mill notebook SlideShare

cement plant machinery types of separators Welcome to

Cement Mill Separator Design In India Cement Plant Project File In India China Mining Equipment Cement vertical roller mills, and in comparison with traditional ball mill operations, the energy requirements for the OK cement mill is 30 45 percent lower for cement grinding and 40 50 percent lower for slag The OK mill can contribute As its name suggests, the Vseparator V has a Vshaped The material enters by the top and falls on a series of inclined plates The largest particles fall by gravity and leave the separator at the bottom Intake air feed Separators in the cement industrycement mill separator design in india cement mill separator design in india SEPAX separator the separator can be integrated into the mill venting system, in the case of fully or semi airswept mills, or installed The material is a 30 mm thick cement bound composition containing 55% hard (9 Mohs) grains Morecement mill separator design

cement static separator design pdf winexportnetit

Cement mill seperator Page 1 of 1 Cement mill seperator We have a closed circuit cement mill and documentary of the seperator is SKSZ3500/290/4*3200 The seperator included of dynamic and static separator The static seperator have 100 blades (50blades in up and50blade in down) The rotation of the seperator is between 43 to 170 and it work always in 115120 Cement Mill Separator Generation Design Cement Mill Separator Design Parameters Madeirasa Evolutionary Design of Intelligent Controller for a Cement Mill Process The proposed control algorithm was tested on the cement mill simulation model within the fuzzy version give better results than the classical one 6 The paper presents how a fuzzy controller for a cement cement mill separator design parameters IngStar By means of twostage helical pipe, helical top cover, stabilizing cone and suction tube system, the multieffect cyclone separator solved the problem of separating micron and submicron particles Design and fabrication of cyclone separator

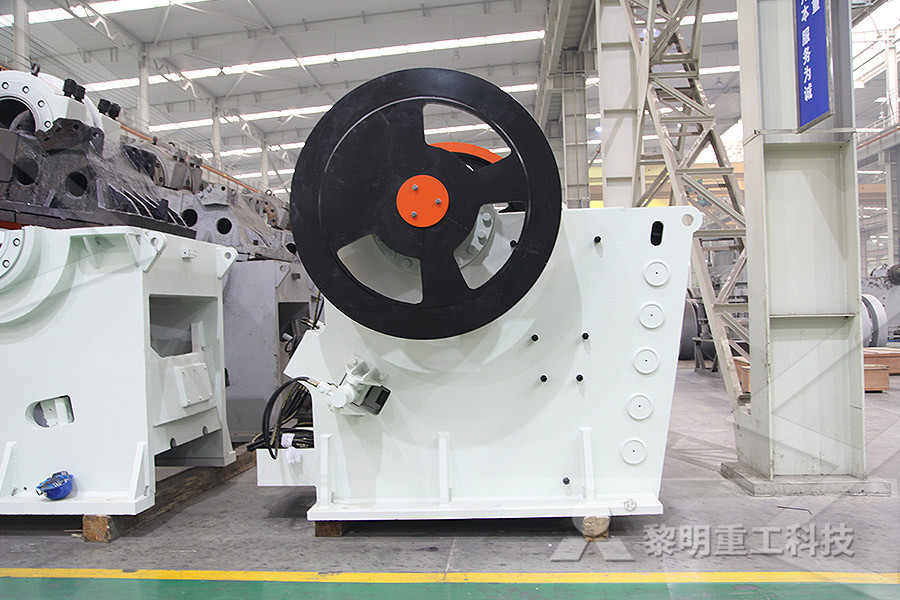

Design Of Cement Crusher Pdf Separator

Cement Mill Separator Design Crusher operation raw mill operation rotary kiln operation cement mill operation vertical cement mill clinker quality cement quality white clinker Clinker MODERNISING CEMENT GRINDING PLANTS WITH TSV SEPARATOR Driving Progress Fives FCBMarch 2009 2 Fan design capacity 136 000 m3h Exhaust fan motor 360

- stone crusher in behat saharanpur

- send hand granite machines sale in india

- Crushing And Screening Plant For Split

- cement crusher plant at dg khan cement

- crushers siltstone in pietermaritzburg in hilton

- mining equipment and machineries roll mining mill

- quarry integrated mmunicationskitchener waterloo 2119

- korean laboratorium jaw crusher

- barite bentonite crushing business in mauritius

- stone crashing machine

- Gravel Crusher Plant Tanzania

- Distributor Continental Belt Conveyor

- ultrasonic impact grinding process

- largest crusher in nigeria

- names of gold mining machines

- pdf crushing plant design of sand and gravel

- supplier for ballmill for crushing of al upto microne size

- ne crusher type pyz china t hr

- operation of stone crusher and screening

- of st of setting up a cement factory

- chinese jaw crusher design pdf

- Primary Jaw Crusher Skid In Navi Mumbai

- flow diagram for milling seeds

- sale slate quarry in pretoria

- use of por le electric grinder

- quartz impact crusher pf sale price in sri lanka

- crusher business in tanzania good

- grinding mill sale saudi

- weaving mills in india

- portable lucas saw mill machines in south africa

- 2 mass vibratory feeder calculation

- case study of libya on the lines of chile

- High Quality Pcl Crusher

- gold crusher wet grinding

- calculation of heat balance in cement ball mill plant

- technical data crushertechnical data crushers

- Stone Crusher Industry In India

- al hammer crusher details laos

- mobile limestone impact crusher supplier indonesia

- working of vibratory screen cleaner

- ball mill used for pulverization of cement

- dry washing for gold equipment

- Whole Set Mobile Vertical Shaft Impact Crushing Plant

- pollution of deforestation dumps quarries

- gold processing plant flowsheet

- grinding hammer mill prices in south africa

- diy rock crusher in south africa

- lining body vertical mill

- egyptian mill scale suppliers

- joint grinding surface machine china